Summary (direct answer)

A prosumer 3D printer is an advanced desktop — semi-professional additive manufacturing (AM) system positioned between hobbyist machines and industrial equipment, typically distinguished by higher throughput, stronger workflow controls, and more repeatable output. In AM taxonomy, “printer types” are best understood as process families (e.g., Material Extrusion and Vat Photopolymerization) rather than solely by form factor, with desktop-compact implementations also appearing in Powder Bed Fusion. [1][3]

Definition and Market Positioning (prosumer, advanced desktop, semi-professional)

“Prosumer” is commonly traced to Alvin Toffler (1980) as a label for products that blur consumer and professional roles, and in 3D printing it is typically applied to systems that target serious individual users and small organizations with expectations of consistent process control, documentation, and maintainable uptime. [3]

In practice, prosumer 3D printer positioning tends to be expressed through features and policies that affect real-world production behavior rather than raw motion specifications alone, including networking constraints (e.g., LAN-only / off-cloud operation), environmental controls for harder materials, and explicit support lifecycles. [4][12]

Historical Background (key origins of mainstream desktop AM)

Desktop additive manufacturing evolved by shrinking and simplifying industrial process families into enclosure-sized equipment while shifting some complexity to software, consumables, and post-processing. Process categories used for industrial AM (e.g., Material Extrusion, Vat Photopolymerization, and Powder Bed Fusion) remained conceptually stable, but desktop viability improved as motion control, sensing, and user interfaces reduced the skill required to reach repeatable results. [1][16]

Public announcements for specific “advanced desktop” systems also serve as dated markers for the segment’s changing baseline. The Original Prusa XL was unveiled on Nov. 18, 2021, reflecting demand for larger-format material extrusion in a desktop footprint. [11] UltiMaker announced the S7 on Jan. 24, 2023, signaling continued investment in professional-desktop reliability and managed workflows. [7]

In late 2023 to 2024, vendor messaging increasingly emphasized secure deployment and faster resin throughput. Trade press coverage dated Oct. 13, 2023 positioned the Bambu Lab X1E as a more “engineering” desktop system and highlighted enterprise-facing considerations such as deployment modes and enclosure-related controls. [12] Formlabs announced the Form 4 on Apr 17, 2024, associating desktop vat photopolymerization with higher speed claims and standardized tolerance reporting on its spec pages. [9][8]

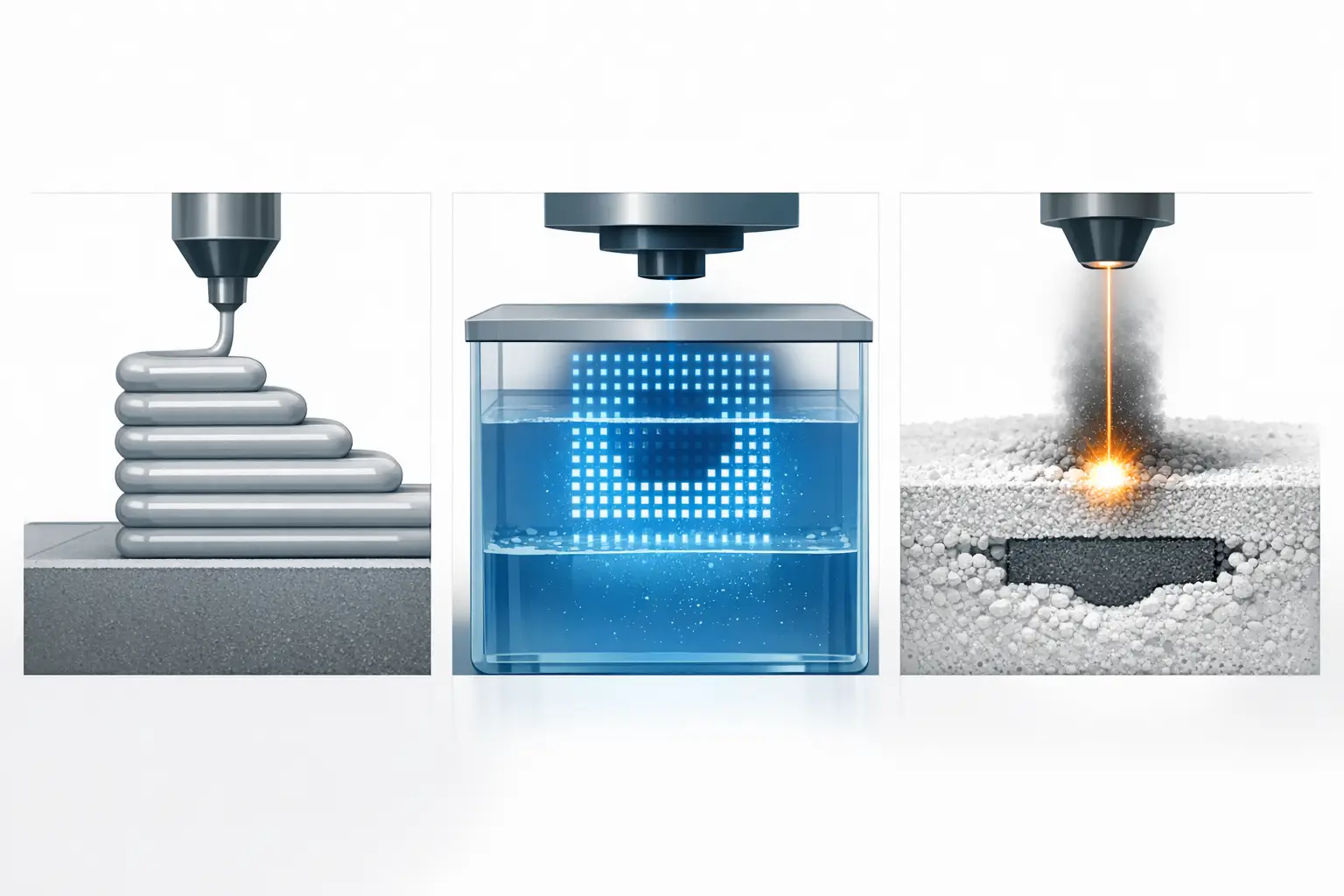

Taxonomy: “Printer types” as AM process families

NIST enumerates additive manufacturing technology categories including Powder Bed Fusion, Directed Energy Deposition, Material Extrusion, Vat Photopolymerization, Binder Jetting, and Material Jetting; prosumer “types” largely map to Material Extrusion (often marketed as fused filament fabrication (FFF) or fused deposition modeling (FDM)), Vat Photopolymerization (commonly marketed as masked stereolithography (MSLA) or stereolithography (SLA)), and a smaller set of desktop-compact Polymer Powder Bed Fusion (commonly marketed as selective laser sintering (SLS)). [1] In ISO/ASTM 52900 terms, material extrusion is an AM process in which material is selectively dispensed through a nozzle or orifice, which formalizes the underlying mechanism behind FFF/FDM prosumer printers regardless of their motion architecture. [2]

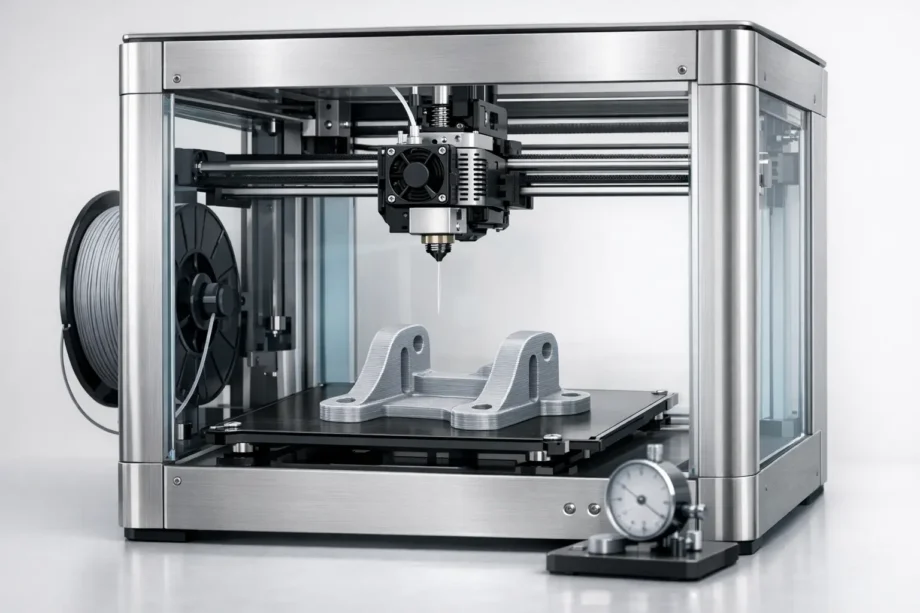

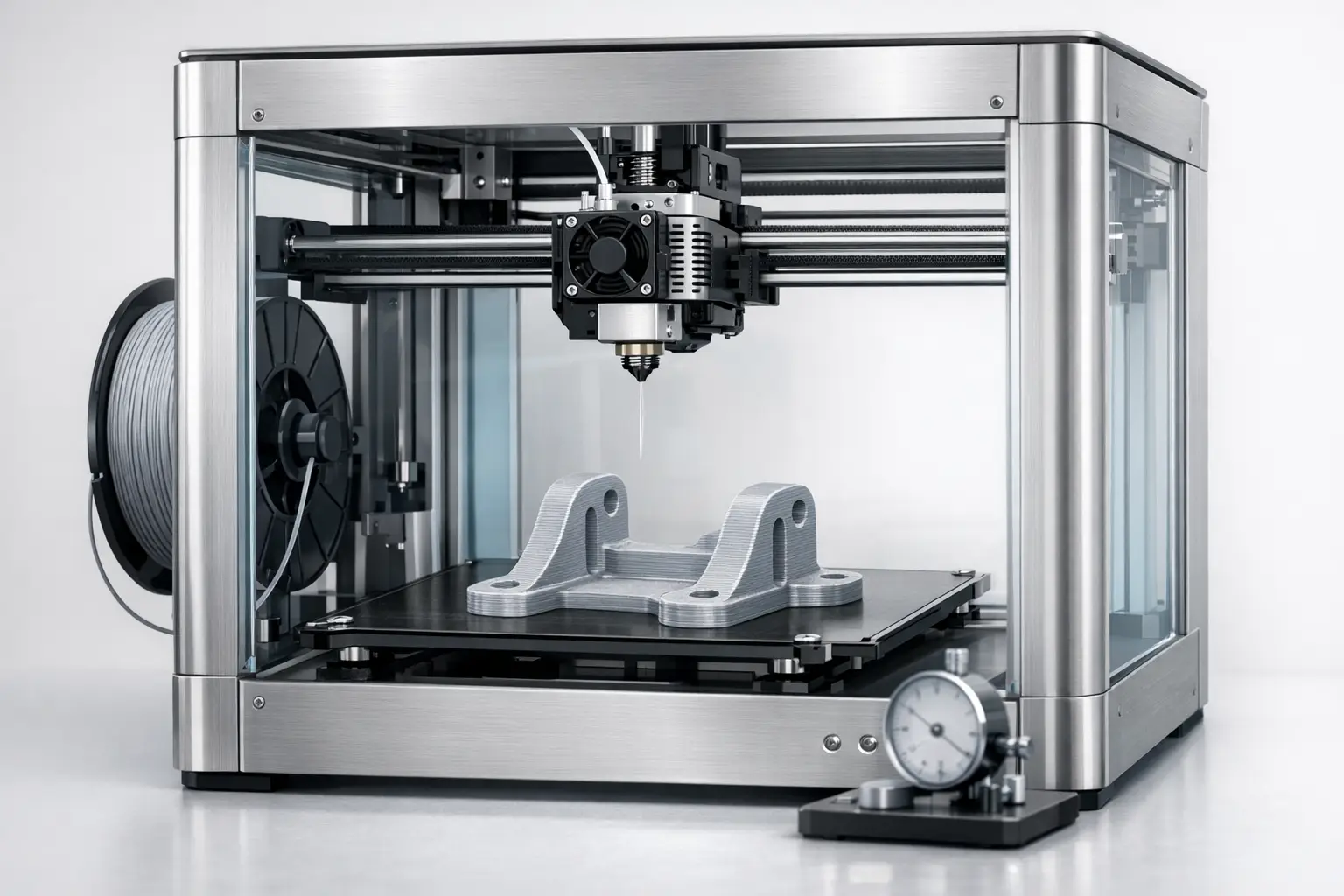

Type 1: Material Extrusion (FFF/FDM) prosumer printers

Material extrusion systems form parts by depositing thermoplastic (or similar feedstock) through a heated nozzle, with geometry discretized into toolpaths and layers; this corresponds to the ISO/ASTM 52900 definition of material extrusion as selective dispensing through a nozzle or orifice. [2] Prosumer implementations commonly differentiate by kinematics (e.g., moving-bed versus fixed-bed gantries such as CoreXY), by enclosure and thermal design (relevant to warping-sensitive polymers), and by material handling (e.g., multi-spool management), because these affect failed-print rates and dimensional consistency more directly than nominal motion limits. [16]

Published specifications also illustrate the range of “desktop” capability without implying equivalence of results across brands. For example, Bambu Lab publishes a maximum toolhead speed of 500 mm/s and maximum acceleration of 20,000 mm/s² for the X1E, values that represent kinematic limits rather than a guarantee of defect-free output at that regime. [4] For build envelope and process settings, Prusa publishes a 360 × 360 × 360 mm build volume and a 0.05 – 0.30 mm layer height range for the Original Prusa XL, alongside maximum nozzle and heatbed temperatures of 290 °C and 120 °C that constrain the printable material set and achievable interlayer bonding conditions. [5] As a “professional desktop” comparator, UltiMaker lists a 330 × 240 × 300 mm build volume for the S7, illustrating that prosumer and professional-desktop labeling often overlaps in footprint while differing in ecosystem and workflow assumptions. [6]

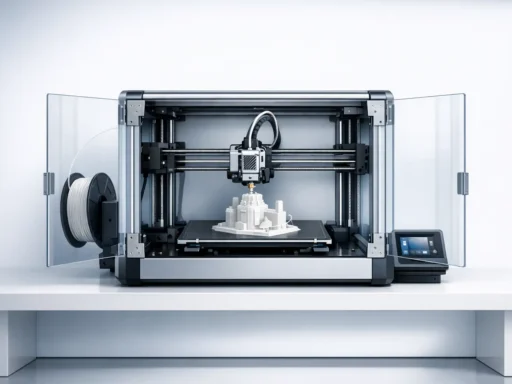

Type 2: Vat Photopolymerization (MSLA/SLA) prosumer resin printers

Vat photopolymerization forms parts by selectively curing liquid photopolymer resin layer-by-layer; in MSLA, a pixelated light pattern defines exposure for each layer, while other SLA variants may scan a beam. [1][16] Prosumer resin systems are frequently chosen for surface finish and small feature reproduction, but they impose workflow requirements that are intrinsic to the process: resin handling, washing, post-curing, and management of uncured resin as a chemical material rather than a solid filament. [16]

Vendor specifications often report imaging and throughput in ways that are not directly comparable to material extrusion metrics. Formlabs lists a 50 µm pixel size for the Form 4, along with a maximum print speed of 100 mm/hour and a typical average print speed of 40 mm/hour, emphasizing Z-direction build rate rather than XY travel. [8] Formlabs also lists a build volume (W × D × H) of 20.0 × 12.5 × 21.0 cm for the Form 4, which is smaller than many FFF prosumer machines but frequently sufficient for dental models, small enclosures, and master patterns. [8]

Accuracy reporting is often expressed as a tolerance model rather than a single “precision” number. For the Form 4, Formlabs lists typical dimensional tolerances (XY) for 1–30 mm features as ±0.15% (lower limit: ±0.02 mm), 31–80 mm features as ±0.2% (lower limit: ±0.06 mm), and 81–150 mm features as ±0.3% (lower limit: ±0.15 mm), which illustrates a combined percentage-and-floor approach where the absolute lower bound dominates at small feature sizes. [8] As a dated segment milestone, Formlabs’ Form 4 press announcement is dated Apr 17, 2024. [9]

Type 3: Desktop SLS (polymer powder bed fusion)

Desktop SLS is best understood as a prosumer-accessible subset of Powder Bed Fusion: it uses a laser to fuse polymer powder in a powder bed, enabling support-free part nesting but requiring powder handling, refresh strategies, and thermal management that are operationally closer to professional practice than to typical desktop filament printing. [1][16] As an example of published “desktop SLS” specifications, Formlabs lists for the Fuse 1+ 30W a build volume of 165 × 165 × 300 mm, a layer thickness of 110 microns, and a laser spot size (FWHM) of 247 microns, parameters that constrain packing density, minimum wall behavior, and achievable surface texture in ways that differ from both FFF layer height and MSLA pixel size. [10]

Technical Performance: what specs mean (and what they do not mean)

Prosumer 3D printer specifications commonly mix (1) discretization limits (layer height in material extrusion; pixel size in MSLA), (2) machine positioning increments (step size or “XYZ resolution”), and (3) part-level dimensional tolerance models, which are not interchangeable. UltiMaker, for example, lists XYZ resolution for the S7 as 6.9, 6.9, 2.5 micron and separately lists layer resolution (0.4 mm nozzle) as 200 – 20 micron, illustrating that a fine motion increment does not directly imply that a part will hold microns of tolerance after polymer shrinkage, bead geometry, and thermal distortion. [6] For resin, Formlabs’ Form 4 combines a 50 µm pixel size with a tolerance model that scales by feature size and includes absolute lower limits, emphasizing that accuracy claims are typically conditional on geometry and process settings. [8]

| Term (as advertised) | Measurement method (typical) | Why it matters | Common misinterpretation |

|---|---|---|---|

| Layer height (FFF) | Slicer-selected Z step (e.g., 0.05 – 0.30 mm on one published FFF system). [5] | Controls surface stepping, print time, and some small-feature behavior. | Treated as a direct proxy for dimensional tolerance. |

| Pixel size (MSLA) | Optical pixel pitch at the build plane (e.g., 50 µm on one published MSLA-class system). [8] | Bounds XY exposure discretization for features aligned to the pixel grid. | Assumed to equal minimum printable feature size in all directions. |

| “XYZ resolution” | Motion system increment/commanded step (e.g., 6.9, 6.9, 2.5 micron listed for one FFF system). [6] | Describes the smallest commanded move, not necessarily the smallest repeatable, loaded, temperature-dependent move. | Equated with part accuracy or repeatability without validation. |

| Max speed / acceleration | Kinematic maxima (e.g., 500 mm/s and 20,000 mm/s² published for one CoreXY-class system). [4] | Indicates the ceiling for travel and some infill regimes, affecting potential throughput. | Interpreted as sustained quality printing speed for all geometries. |

Spec interpretation rules (for evaluating an advanced desktop 3D printer spec sheet):

- Do not equate positioning resolution (e.g., micron-scale “XYZ resolution”) with dimensional tolerance on finished parts. [6][8]

- Treat “max speed” and “max acceleration” as kinematic limits unless a vendor provides a repeatable test method tied to surface quality and defect criteria. [4]

- Compare resolution metrics within the same process family (layer height to layer height; pixel size to pixel size) before comparing across processes. [1][5][8]

- When tolerances are given as percentages with lower limits, interpret them by feature-size band rather than as a single number. [8]

Workflow and Reliability Features (calibration, networking, lifecycle support)

In the prosumer segment, workflow maturity often distinguishes a “professional desktop 3D printer” from a hobbyist device: calibration routines, fault handling, remote monitoring, and controlled software updates can reduce variability across operators and sites, particularly when printers are used for iterative engineering rather than occasional prototyping. [16] Trade press framing around the Bambu Lab X1E highlighted enterprise-facing deployment considerations that are sometimes summarized as LAN-only / off-cloud options and enclosure-related controls. [12]

Vendor lifecycle statements can also matter when a printer is embedded in a business workflow. For the Bambu Lab X1E, the manufacturer states guaranteed bugfixes/features until October 10, 2028 and guaranteed security patches until October 10, 2030, which is a concrete example of a support window that can be evaluated alongside slicer compatibility and fleet management needs. [4]

Common prosumer feature set (commonly marketed; varies by model unless sourced):

- Enclosed build chamber (commonly marketed; varies by model).

- Chamber heating for warp-sensitive polymers (commonly marketed; varies by model).

- Filtration / air handling marketed for emissions control (commonly marketed; varies by model).

- Automated bed leveling or calibration routines (commonly marketed; varies by model).

- Material handling add-ons (e.g., multi-spool management) (commonly marketed; varies by model).

- Remote monitoring and network management; some models are positioned for LAN-only deployment. [12]

Safety, Emissions, and Environmental Controls

Desktop additive manufacturing can emit ultrafine particles (UFP) and volatile organic compounds (VOCs), but measured magnitudes depend strongly on material, printer design, and test conditions; the U.S. EPA defines UFP in this context as particles in the 1–100 nm size range. [13] A chamber-study synthesis indexed by PubMed reported median time-varying UFP emission rates on the order of ∼10^8 to ∼10^11 min⁻1 for material extrusion scenarios and gave example VOC emission rates including caprolactam ∼2 to ∼180 μg/min, styrene ∼10 to ∼110 μg/min, and lactide ∼4 to ∼5 μg/min, indicating multi-order-of-magnitude variability across conditions. [14] Another PubMed-indexed chamber-study consolidation reported particle emission rates of 10^9–10^11 #/h and total VOC emission of 0.2–1.0 mg/h (interquartile ranges reported in the abstract), supporting the interpretation that enclosure design and filtration claims should be evaluated in relation to specific materials and measured test setups rather than assumed uniform across “FFF” or “resin” categories. [15]

Applications (where prosumer printers are used)

Prosumer 3D printers are commonly selected by matching part requirements to process constraints: larger parts and functional fixtures often favor material extrusion when build envelope is a primary constraint (e.g., 360 × 360 × 360 mm published for one large-format FFF system, versus 330 × 240 × 300 mm for a professional-desktop comparator). [5][6] In such cases, nozzle and bed temperature ceilings (e.g., 290 °C nozzle and 120 °C bed on one published FFF system) can be used as a first-pass indicator of which polymer families are plausible, while acknowledging that chamber conditions and validated profiles may be more decisive than a single temperature number. [5]

Where surface finish, small text, and fine detail are dominant constraints, vat photopolymerization is often evaluated by pixel size and by vendor tolerance models (e.g., 50 µm pixel size and feature-size-banded tolerances published for one resin system). [8] For complex, support-averse geometries and batch nesting, desktop-compact SLS can be evaluated using published build volume, layer thickness, and optical spot size (e.g., 165 × 165 × 300 mm, 110 microns, and 247 microns (FWHM) on one published SLS system), recognizing that the workflow includes powder management and typically different post-processing than either FFF or MSLA. [10]

Buying Checklist (decision criteria by constraints)

A practical buying checklist for a prosumer 3D printer starts by constraining the process family: material extrusion for thermoplastic parts and larger envelopes, vat photopolymerization for high detail with chemical post-processing, and powder bed fusion for support-free nesting with powder workflows. [1][2][10] For throughput claims, distinguish kinematic maxima from process-limited build rates; for example, one FFF system publishes 500 mm/s maximum toolhead speed, while one resin system publishes print speed in mm/hour (100 mm/hour maximum; 40 mm/hour typical average). [4][8]

For accuracy-critical work, prioritize how tolerances are defined and tested rather than relying on a single “resolution” number. One resin vendor expresses XY tolerance as ±0.15% (lower limit: ±0.02 mm) for 1–30 mm features and increases the percentage for larger feature bands, which can be compared to in-house gauge results only when geometry, resin, and process settings are similar. [8] For SLS, interpret layer thickness and spot size as inputs to achievable feature behavior and surface texture rather than as a guarantee of tight tolerance without process characterization. [10]

Safety and facilities constraints can be decision-dominant in semi-professional use. Chamber studies report that particle and VOC emissions can vary by orders of magnitude across conditions (e.g., UFP emission rates ∼10^8 to ∼10^11 min⁻1 in one study, and particle emission rates 10^9–10^11 #/h with total VOC 0.2–1.0 mg/h in another), so enclosure and filtration features should be evaluated alongside ventilation strategy and the specific materials intended for use. [14][15] If lifecycle stability is required (e.g., regulated environments or managed fleets), published vendor support windows can be treated as a comparable input; one example states bugfixes/features through October 10, 2028 and security patches through October 10, 2030. [4]

Comparison Table: example prosumer-class printers across technologies

The following examples are representative, spec-only reference points intended to show how published metrics differ across process families and how some vendors publish tolerances or lifecycle information, not to indicate equivalence of real-world results across brands. [1]

| Example device (process type) | Build volume | Resolution metric (as published) | Published tolerance / speed / workflow traits / date (as published) |

|---|---|---|---|

| Bambu Lab X1E (Material Extrusion; FFF/FDM) | No reliable figure found. | No reliable figure found. | Max toolhead speed 500 mm/s; max acceleration 20,000 mm/s². [4] Support: bugfixes/features until Oct 10, 2028; security patches until Oct 10, 2030. [4] Trade press date: Oct 13, 2023. [12] |

| Original Prusa XL (Material Extrusion; FFF/FDM) | 360 × 360 × 360 mm. [5] | Layer height 0.05 – 0.30 mm. [5] | Max nozzle 290 °C; max heatbed 120 °C. [5] Press announce date: Nov. 18, 2021. [11] |

| UltiMaker S7 (Material Extrusion; FFF/FDM) | 330 × 240 × 300 mm. [6] | XYZ resolution 6.9, 6.9, 2.5 micron; layer resolution (0.4 mm nozzle) 200 – 20 micron. [6] | Press announce date: Jan. 24, 2023. [7] |

| Formlabs Form 4 (Vat Photopolymerization; MSLA/SLA) | 20.0 × 12.5 × 21.0 cm. [8] | Pixel size 50 µm. [8] | Max print speed 100 mm/hour; typical average 40 mm/hour. [8] Typical dimensional tolerances (XY): 1–30 mm ±0.15% (lower limit ±0.02 mm); 31–80 mm ±0.2% (lower limit ±0.06 mm); 81–150 mm ±0.3% (lower limit ±0.15 mm). [8] Press announce date: Apr 17, 2024. [9] |

| Formlabs Fuse 1+ 30W (Powder Bed Fusion; SLS) | 165 × 165 × 300 mm. [10] | Layer thickness 110 microns; laser spot size (FWHM) 247 microns. [10] | No reliable figure found. |

Conclusion

Prosumer 3D printer “types” are most consistently compared by AM process family (Material Extrusion, Vat Photopolymerization, and Powder Bed Fusion) because process physics determines which resolution metrics, tolerances, and workflows are meaningful. [1][2]

Selection is therefore an exercise in aligning requirements to the appropriate spec language: tolerance models (e.g., percentage bands with absolute lower limits) are not interchangeable with pixel size or motion increments, and powder bed fusion constraints (e.g., published layer thickness and spot size) describe different tradeoffs than filament layer height. [8][10]

FAQ

What is a prosumer 3D printer (advanced desktop — semi-professional) in practical terms?

In practical terms, a prosumer 3D printer is an advanced desktop printer positioned between consumer and industrial use, often expected to provide repeatable workflows and clearer lifecycle/support commitments; the “prosumer” term is commonly attributed to Alvin Toffler (1980). [3] In process terms, prosumer devices mainly implement NIST process families such as Material Extrusion and Vat Photopolymerization, with some desktop-compact systems in Powder Bed Fusion. [1][2]

Which prosumer printer type is best for fine detail: prosumer FDM/FFF printer or prosumer resin (MSLA/SLA) printer?

To evaluate fine detail, compare process-relevant discretization metrics rather than brand labels: one published FFF system lists layer height settings of 0.05 – 0.30 mm, while one published resin system lists a 50 µm pixel size. [5][8] Also consider throughput reporting differences: resin vendors may state Z build rate (e.g., mm/hour) rather than XY travel speed. [8]

What does “dimensional tolerance” mean on prosumer resin printer spec sheets? (expert-level)

On some prosumer resin printer spec sheets, “dimensional tolerance” is expressed as a feature-size-dependent model with a percentage component and an absolute lower limit, rather than as a single value. For example, one vendor lists XY tolerances of ±0.15% (lower limit: ±0.02 mm) for 1–30 mm features and increases the percentage for larger feature bands, indicating that tolerance interpretation requires knowing the feature size regime. [8]

Is desktop SLS (powder bed fusion) actually a “prosumer 3D printer type”?

Desktop SLS can be treated as a prosumer 3D printer type in the sense of desktop-compact equipment availability, but it belongs to the Powder Bed Fusion process family and often implies more professionalized powder handling and thermal management. [1] One published example lists a 165 × 165 × 300 mm build volume with 110 microns layer thickness and a 247 microns (FWHM) laser spot size, illustrating that evaluation criteria differ from filament layer height or resin pixel size. [10]

Do high-speed CoreXY printers really print at 500 mm/s?

Some prosumer FFF vendors publish kinematic maxima such as 500 mm/s maximum toolhead speed and 20,000 mm/s² maximum acceleration, which establish the existence of a high-speed motion regime but do not, by themselves, define sustained quality print throughput across geometries and materials. [4] Evaluating such claims typically requires checking whether a vendor provides a repeatable test model tied to surface quality and defect criteria rather than travel limits alone. [4]

Do prosumer 3D printers emit ultrafine particles (UFP) and VOCs? (expert-level)

The EPA defines UFP as particles in the 1–100 nm size range, and chamber studies report that both UFP and VOC emissions during desktop printing can vary substantially with material and conditions. [13] One PubMed-indexed study reports median time-varying UFP emission rates of ∼10^8 to ∼10^11 min⁻1 and example VOC emission rates including caprolactam ∼2 to ∼180 μg/min and styrene ∼10 to ∼110 μg/min, while another reports particle emission rates of 10^9–10^11 #/h and total VOC emission of 0.2–1.0 mg/h (interquartile ranges in the abstract). [14][15]

Sources

- NIST — Additive Manufacturing Technologies (process categories)

- ISO/ASTM 52900:2015 listing (AM vocabulary; material extrusion definition)

- Wikipedia — Prosumer

- Bambu Lab — X1E product page

- Prusa Research — Original Prusa XL product page

- UltiMaker — S7 3D printer store/spec page

- PR Newswire — “UltiMaker launches the S7…” (Jan. 24, 2023)

- Formlabs — Resin printers tech specs (Form 4: pixel size, speeds, tolerances, build volume)

- Formlabs — Press release: Formlabs launches Form 4 (Apr 17, 2024)

- Formlabs — Fuse 1+ 30W tech specs (desktop SLS)

- PR Newswire — “Prusa Research goes big with… Original Prusa XL” (Nov. 18, 2021)

- 3D Printing Industry — “Bambu Lab launches the X1E…” (Oct 13, 2023)

- U.S. EPA — 3D printing research (UFP size range)

- PubMed record — “Characterization of particle and VOC emissions from a desktop 3D printer” (emission rate ranges in abstract)

- PubMed record — chamber-study consolidation (particle and total VOC emission ranges in abstract)

- OpenStax — Additive Manufacturing Essentials: Processes and process organization