Summary

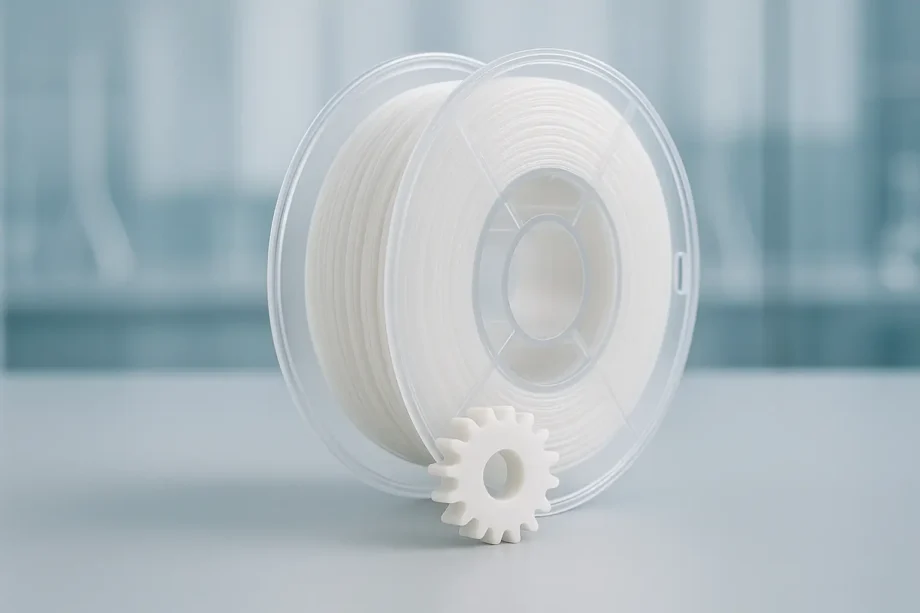

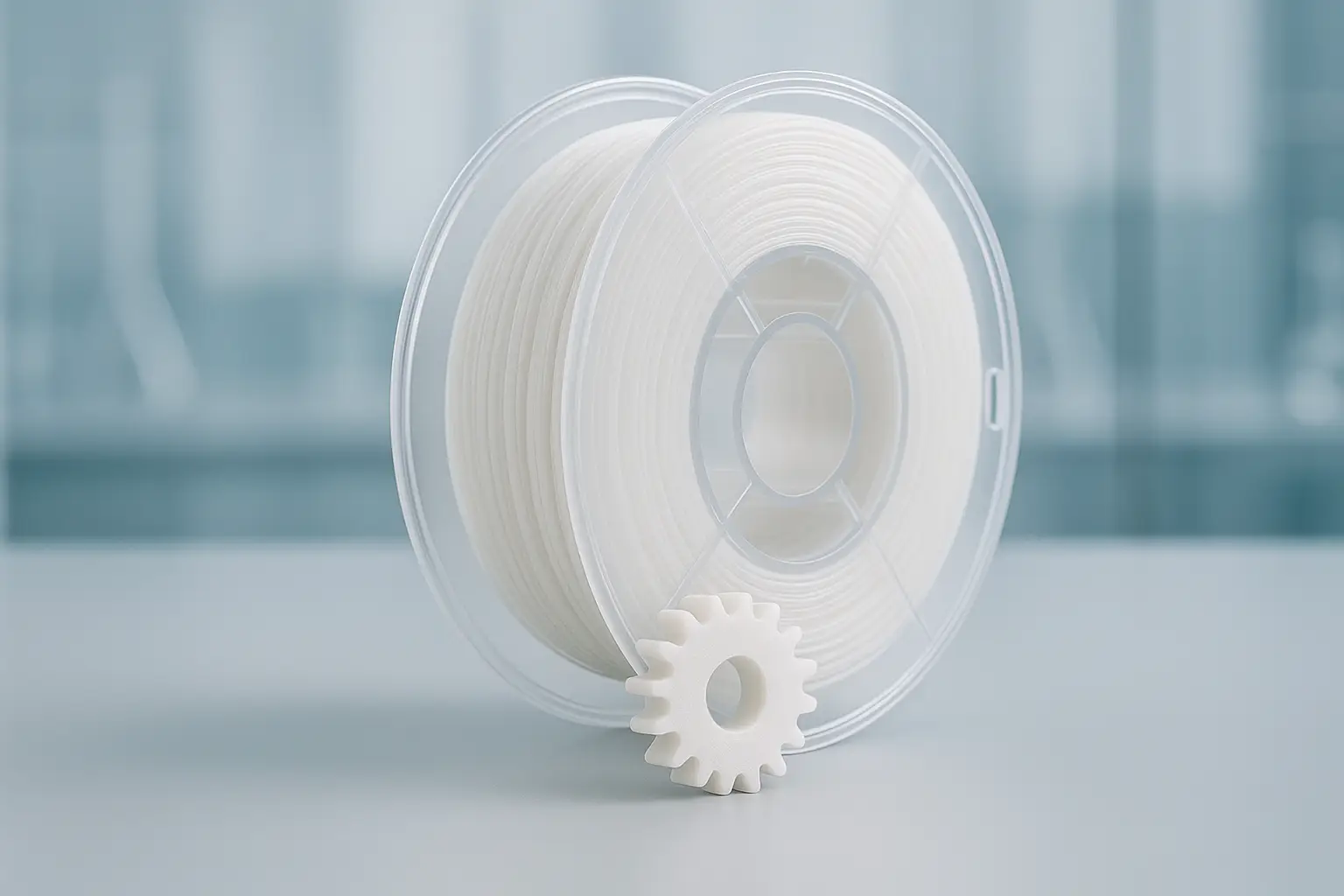

Nylon filament is a high-performance engineering filament widely used in 3D printing for its exceptional strength, durability, and flexibility. Most commonly selected for functional prototypes and end-use parts, nylon 3D printing filament excels in producing robust mechanical components. Its semi-crystalline structure and resistance to chemicals make it a go-to choice for demanding applications.

Historical Background

Nylon was originally invented by Wallace Carothers at DuPont in the United States during the 1930s (no reliable figure found — primary source missing, reference: Wikipedia). Initially developed for use in fibers and plastics, nylon’s advantageous strength and thermal resilience led to rapid adoption in engineering applications. The material was later adapted for additive manufacturing, becoming a leading option as a 3D printing filament. Repurposing traditional injection-grade nylon for fused deposition modeling (FDM) and selective laser sintering (SLS) enabled its use in industrial prototyping and small-batch functional parts.

Technical Principles

Nylon is a semi-crystalline thermoplastic, exhibiting both strength and flexibility. It is known for being a highly moisture-sensitive filament, with PA12 absorbing ~2–3 % and PA6 up to ~6–9 % of its weight from air, requiring thorough drying before printing to maintain quality (jcproto.com).

Types

Nylon filaments exist in major variants, including PA6, PA66, PA11, and PA12. PA6 filament displays a tensile modulus of 850/1900 MPa and a tensile strength of 37 MPa; PA66 offers 2000/2100 MPa modulus and 42 MPa tensile strength. PA11/12 typically exhibit a lower modulus (600/1200 MPa), tensile strength of 25 MPa, but notable elongation (>50 %) and impact resistance (rupturetech.com).

Filled and unfilled nylons offer different performance balances. Unfilled PA12 presents tensile strengths of 45–55 MPa for FDM (jcproto.com), while SLS/MJF-printed Nylon 12 achieves 48 MPa. Composite nylons such as PA12 glass-filled (SLS) yield 36 MPa tensile strength but display much higher modulus and temperature resistance. Carbon fiber and glass fiber blends further tune mechanical properties (fictiv.com).

Performance

Mechanical metrics

Nylon filament exhibits a wide spectrum of mechanical properties depending on type and process. Unfilled PA12 typically reaches 45–55 MPa tensile strength in FDM (jcproto.com), whereas MakerBot nylon measures 66 MPa and PA12 SLS/MJF reaches 48 MPa with elongation at break of 20% (fictiv.com). Filled nylons such as PA12 glass-filled have a reduced elongation (2%) but triple the modulus (3200 MPa). High-performance filaments like DSM Novamid ID1070 offer a yield stress of 77 MPa and strain at break exceeding 50% (juggerbot3d.com).

Thermal & processing

Nylon filaments typically melt around 255 °C, with heat deflection temperatures (HDT) ranging from 70 °C to 104 °C depending on the formulation (divbyz.com). Glass-filled variants can endure up to 179 °C (fictiv.com). Proper print temperatures for PA6/66 filaments fall in the 240–260 °C range, usually requiring an enclosed print chamber and bed temperature of 60 °C (rupturetech.com).

| Variant | Tensile Strength (MPa) | Modulus (MPa) | Elongation (%) | Heat Resistance (°C) |

|---|---|---|---|---|

| PA6 | 37 | 850/1900 | >20 | 70 |

| PA66 | 42 | 2000/2100 | 10 | 90 |

| PA11/12 | 25 | 600/1200 | >50 | 90 |

| PA12 (FDM, unfilled) | 45–55 | — | — | — |

| PA12 (SLS/MJF) | 48 | 1500/1935 | 20 | — |

| PA12 Glass-Filled (SLS) | 36 | 3200 | 2 | 179 |

| Novamid ID1070 | 77 | 2590 | >50 | 104 |

| MakerBot Nylon (FDM) | 66 | >2200 | — | 91 |

| Source: jcproto.com, fictiv.com, juggerbot3d.com, rupturetech.com, makerbot.com, divbyz.com |

Applications

Nylon filament finds primary use in functional prototypes, end-use gear assemblies, snap-fit parts, bushings, and wear-resistant components. Applications also include automotive ducts, machine housings, and robotics—contexts where a high-strength nylon or engineering filament excels due to its resilience and flexibility. Popularity stems from its suitability for demanding engineering solutions (fictiv.com).

Research Updates

Recent research explores carbon fiber and glass fiber reinforcements, boosting nylon’s tensile strength up to 68 MPa while maintaining considerable flexibility and reducing part weight. These advanced composite filaments address the need for lightweight yet high-strength components in aerospace and automotive sectors (wisdomlib.org).

FAQ

What makes nylon filament a preferred engineering filament?

Nylon filament combines high strength, good toughness, wear resistance, and chemical stability, positioning it as a preferred engineering material for 3D printing applications that demand durability and flexibility (divbyz.com).

How does nylon filament compare in tensile strength across PA types?

Tensile strength varies by type: PA6 (37 MPa), PA66 (42 MPa), PA12 (45–55 MPa FDM), and MakerBot nylon up to 66 MPa. Filled variants can further alter this range (jcproto.com, makerbot.com).

How does moisture affect nylon 3D printing?

Nylon’s hygroscopic nature causes it to absorb moisture (up to 2–3 % for PA12, 6–9 % for PA6), potentially leading to print defects like bubbling and weak interlayer bonds if not properly dried before use (jcproto.com).

What are the optimal print settings for nylon filament?

Optimal printing conditions for nylon include 240–260 °C nozzle temperature, 60 °C heated bed, enclosed chamber, and controlled humidity to prevent moisture uptake (rupturetech.com).

How do CF-filled and GF-filled nylon composites affect tensile performance?

Carbon fiber (CF) and glass fiber (GF) reinforcement substantially increase tensile strength — up to 68 MPa — and stiffness but may lower elongation, offering improved mechanical properties for advanced applications (wisdomlib.org).

What design considerations are necessary for nylon 3D printing (e.g., warping, enclosure)?

Design for nylon 3D printing must address warping and moisture sensitivity. Using an enclosed heated chamber, slow cooling, and controlling humidity are essential to minimize print defects and ensure dimensionally stable, high-strength parts (divbyz.com).