Summary

Multi‑Jet Fusion (MJF) is an industrial 3D printing technology developed by HP, recognized for its rapid build speed, high part isotropy, and precise resolution. MJF utilizes a powder bed fusion process with inkjet fusing agents, enabling build volumes up to 380 × 284 × 380 mm and vertical resolutions of 0.08 mm. This process delivers strong, accurate parts with standard tolerances of ±0.3 % (minimum ±0.3 mm), making it highly competitive for producing functional prototypes and end-use components. [1][2][3]

Historical Background

Hewlett‑Packard introduced Multi‑Jet Fusion (MJF) in 2016, debuting in Palo Alto, USA. HP entered the 3D printing market aiming to address prototyping and small-series functional parts with an entirely new approach to powder bed fusion.[1]

Technical Principles

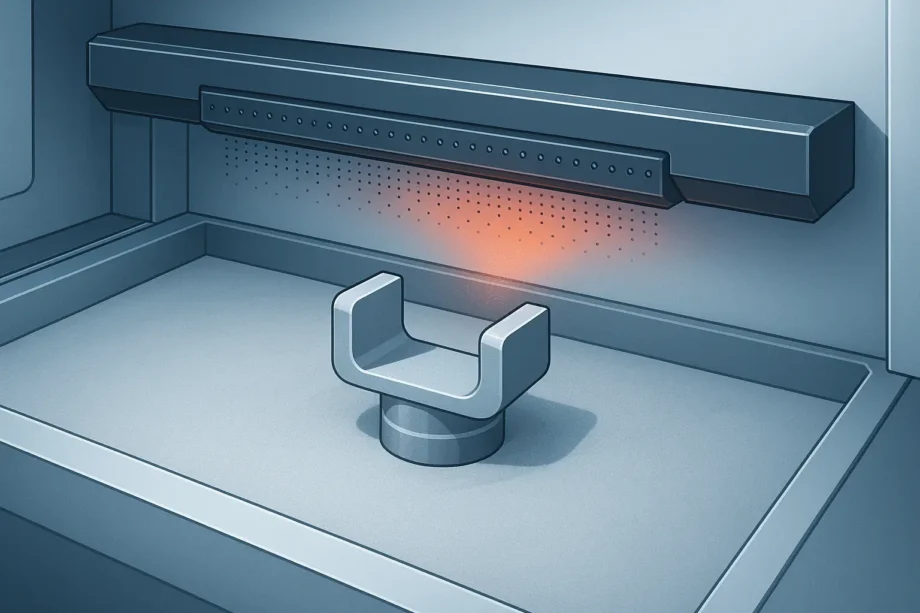

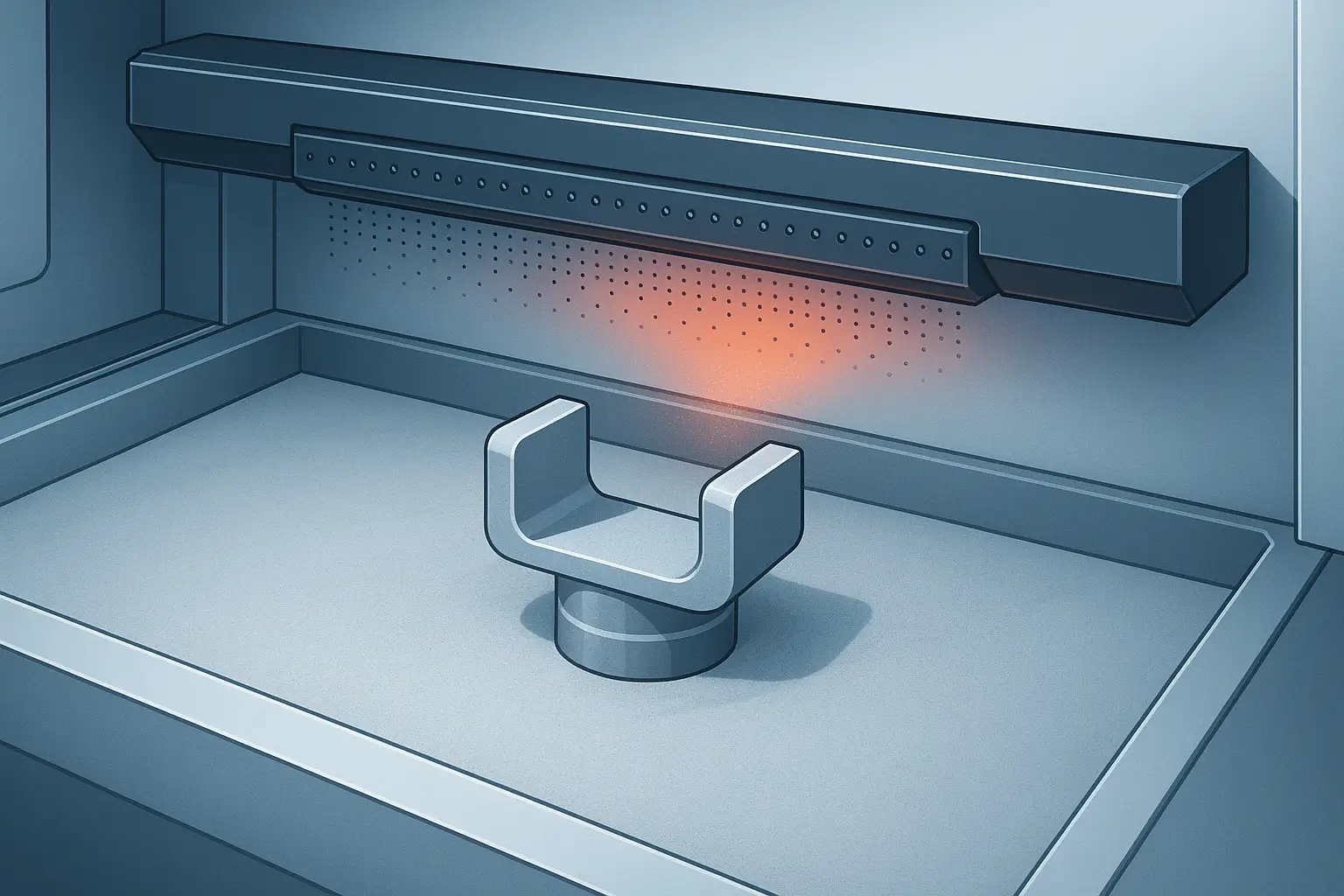

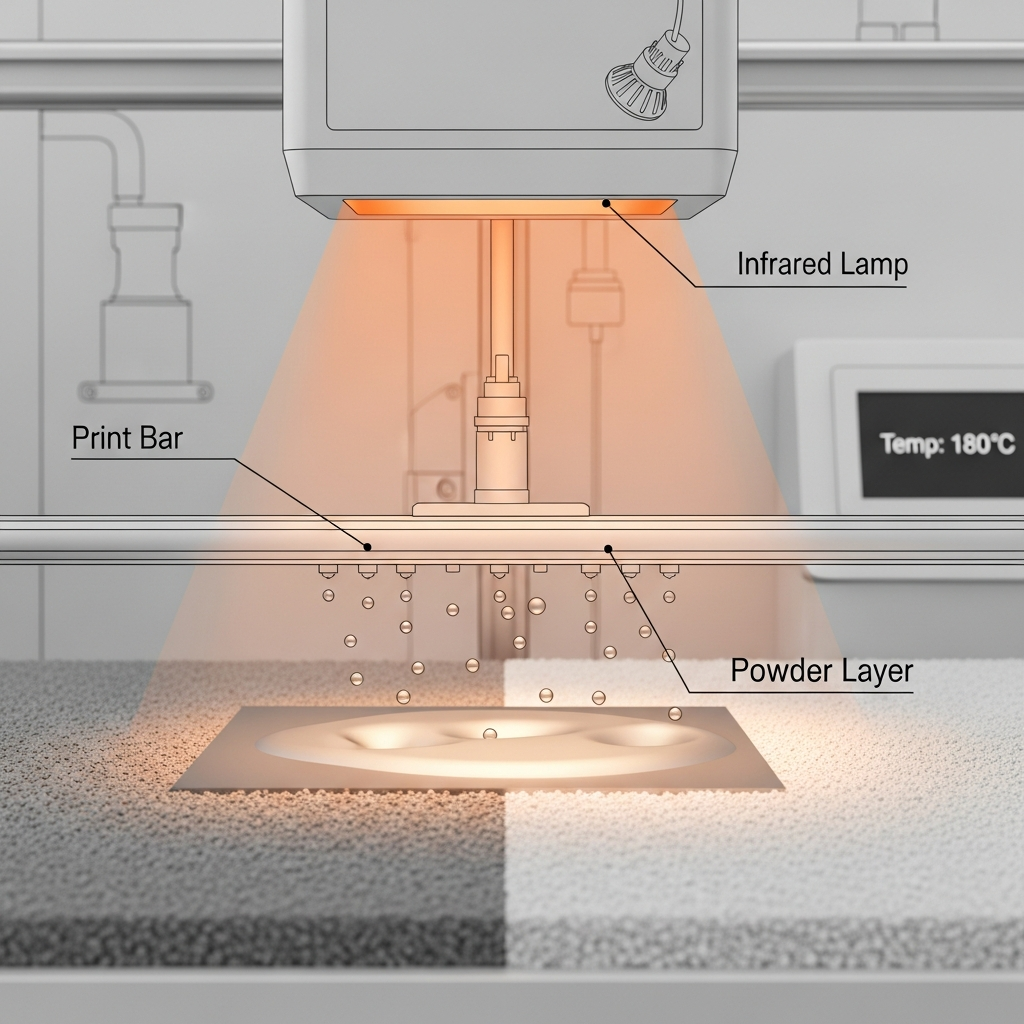

Multi‑Jet Fusion employs a powder bed fusion method where layers of polymer powder are selectively fused using inkjet-printed fusing and detailing agents. After each powder layer is deposited, a print bar jets microscopic droplets of fusing and detailing agents, then an infrared (IR) lamp fuses targeted regions, forming solid cross-sections. MJF’s thermal process eliminates the need for support structures, allowing for complex geometries and minimal post-processing. [4]

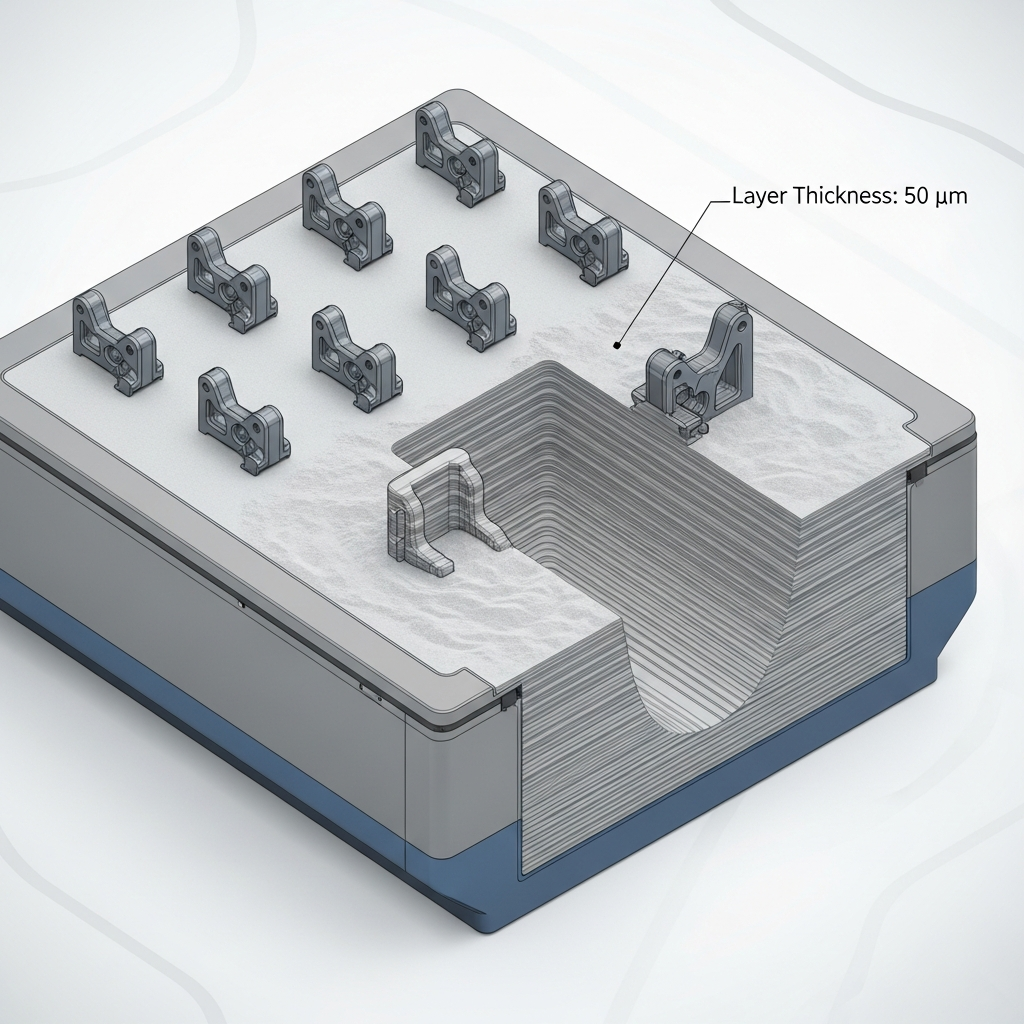

MJF systems offer a vertical resolution (layer thickness) of 0.08 mm (80 µm), enabling the production of smooth, detailed parts. The inkjet printheads operate at 1 200 dpi, ejecting 30 million drops per second per inch of bed width and forming each 2D layer in 16 seconds. Typical build volumes reach 380 × 284 × 380 mm, suitable for batch manufacturing and large multipart assemblies. [2][3][5][6]

Performance

Performance — Speed & Throughput

HP’s high‑end MJF 5200 system achieves a build speed of 5 058 cm³/hr, supported by its proprietary print bar technology. The platform forms each layer in just 16 seconds by dispensing 30 million droplets per second per linear inch of bed width. Compared to selective laser sintering (SLS), MJF often delivers considerably faster print times for comparable part volumes. Editors are encouraged to include a comparison table showing build speeds of the MJF 5200 versus modern high-speed sintering (HSS) systems for reference. [6][7]

Performance — Accuracy & Isotropy

Multi‑Jet Fusion produces highly accurate components with standard dimensional tolerances of ±0.3 % or a minimum of ±0.3 mm, ideal for precision engineering. MJF parts exhibit isotropy levels of 97–98 %, offering near-uniform mechanical properties across all axes, unlike many layered 3D printing processes. A summary of PA‑12 part mechanical properties:

- Tensile strength: 48 MPa

- Tensile modulus: 1 700 MPa

- Elongation at break: 20 %

These characteristics enable robust designs suitable for demanding applications. [5][8][9]

Performance — Sustainability & Materials

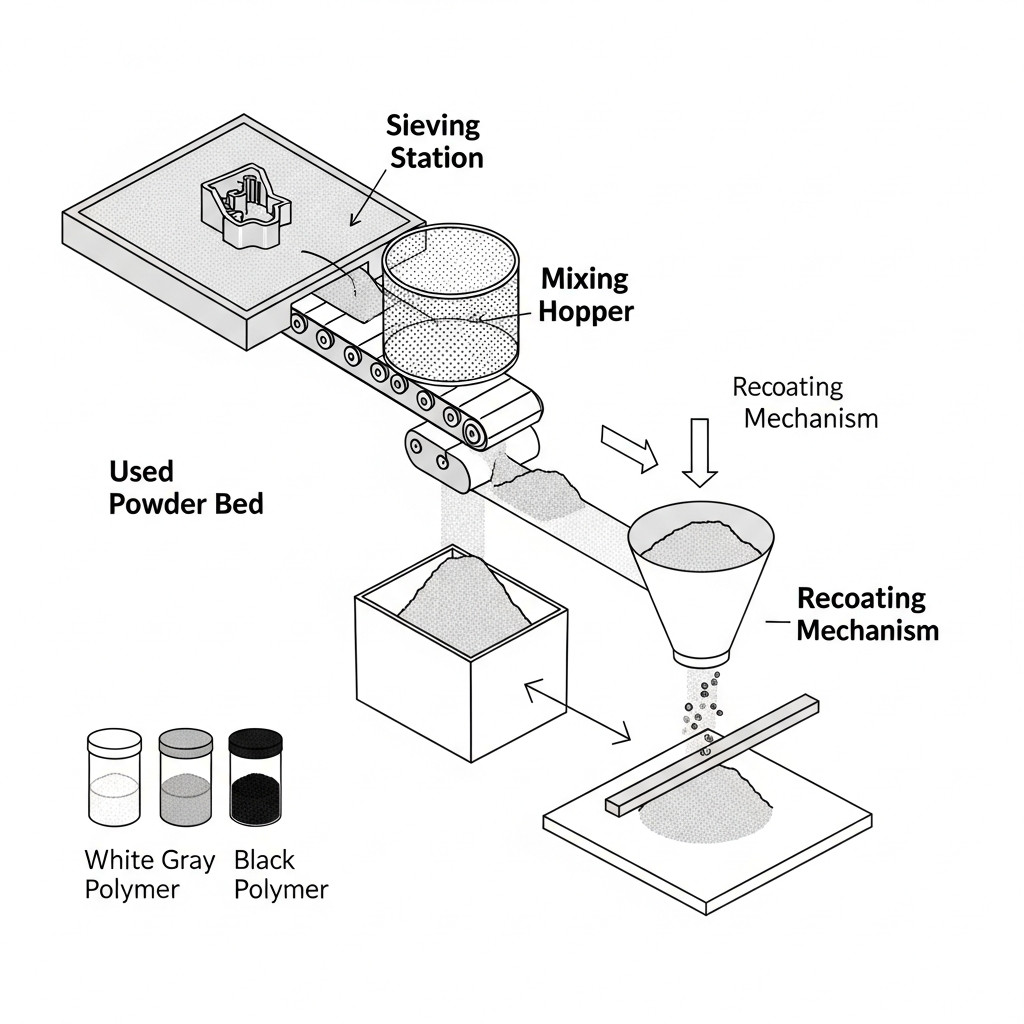

MJF systems are designed for efficiency, as 80–85 % of unused polymer powder can be recycled for subsequent print jobs, reducing operational costs and waste. The technology supports a growing list of materials, including:

- Polyamide‑12 (PA‑12)

- Polyamide‑11 (PA‑11)

- Thermoplastic polyurethane (TPU)

- Polypropylene (PP)

This range allows for diverse application requirements and performance needs. [10]

Applications

Multi‑Jet Fusion is widely used for rapid prototyping, bridge production, and manufacturing low- to medium-volume batches. Application domains include the automotive industry (custom interior parts, housings), healthcare (prosthetic devices, orthotics), consumer electronics, and industrial tooling. [8][11]

A key advantage of MJF is the ability to produce intricate, highly functional parts with no need for support structures, translating to significant time and cost savings. Many MJF-printed parts offer mechanical strength comparable to injection-molded components, via the high isotropy and dense, well-fused structures. Speed benchmarks from TriMech and RapidMade show MJF consistently surpasses traditional SLS in throughput while maintaining quality. [7][8]

Research Updates

Recent overviews, such as the 2021 ASME review, highlight ongoing R&D focused on expanding compatible materials — including new thermoplastic elastomers like those developed by Evonik in 2020 and 2024. These developments strengthen MJF’s position for both flexible and engineering-grade part applications. [1]

FAQ

1. What is the typical accuracy of HP MJF prints?

MJF parts are produced with a standard accuracy of ±0.3 % or a minimum of ±0.3 mm, suitable for demanding engineering applications. [5]

2. How fast can Multi Jet Fusion produce parts?

A flagship system like the MJF 5200 can reach a throughput of 5 058 cm³/hr, printing each layer in approximately 16 seconds. [6][7]

3. What materials are compatible with powder bed fusion MJF?

Supported materials are PA‑12, PA‑11, TPU, and polypropylene (PP), with ongoing material expansion. [10]

4. How isotropic are HP MJF parts compared to SLS?

MJF achieves 97–98 % isotropy, often exceeding that of SLS parts and leading to more uniform mechanical performance in all directions. [9]

5. What are the dimensional tolerances when using HP MJF for precision engineering?

HP MJF systems offer standard dimensional tolerances of ±0.3 % (not less than ±0.3 mm), as specified by manufacturers. [5]

6. How much powder can be recycled in Multi Jet Fusion environments?

Between 80–85 % of unused powder from each MJF print job can be reused in future prints, minimizing material waste. [10]

Sources

- Multi Jet Fusion — Wikipedia

- TimeTo3D — HP Jet Fusion 5200 series specs

- Forerunner 3D Printing — MJF build volume details

- TriMech — How HP MJF Works

- 3Faktur — MJF – Technology Profile

- voxeljet — Polymer 3D Printing System Comparison

- TriMech — HP MJF Speed Comparison

- RapidMade — HP MJF Applications

- Forerunner 3D Printing — Material Properties

- P3D MFG — MJF Powder Reuse Explained

- ASME – Advancements in 3D Printing (2021)