Summary

Metal infused filament—also called metal-filled PLA or bronze PLA—is a composite 3D printing material comprised of a thermoplastic base and high concentrations of fine metal powder. Metal content typically ranges from 60 % to over 90 % by weight, enabling production of objects with both metallic weight and appearance on standard FDM printers. These filaments have become essential for creating realistic metal-like prints without the complexity of traditional metal additive manufacturing. [1][7][8]

Historical Background

The first widely recognized metal-infused filament, BronzeFill, was commercialized by ColorFabb in the Netherlands circa 2014. This innovation aimed to provide hobbyists and designers with the capability to print bronze-like decorative models using desktop 3D printers, marking the practical origin of this technology in consumer markets. [9]

Principles of Metal-Infused Filament

Metal-infused filaments are engineered by blending a polymer matrix—most commonly polylactic acid (PLA) or heat-treated PLA (HTPLA)—with finely powdered metals such as bronze, copper, or brass. The proportion of metal can significantly influence the material’s properties. For example, Formfutura’s MetalFil Ancient Bronze contains approximately 60 % bronze by weight, while Filabot’s Bronze Filamet boasts metal fractions as high as 88–90 %. HP technical resources indicate that for filaments designed for potential metal-parts sintering, around 80 % metal powder is typical, offering a continuum between aesthetic and functional metallic prints. [1][7][8]

The addition of dense metal powder alters both the physical and functional characteristics of the filament. Heavier spools—such as Spectrum PLA Metal Bronze with a density of 2.28 g/cm³ and MetalFil’s 3.5 g/cm³—create substantial objects. Increased filler also means greater mechanical stress on printers: dimension tolerance is critical, with reputable brands offering ± 0.03 mm diameter consistency for reliable extrusion. However, abrasive metal particles accelerate nozzle wear, necessitating the use of hardened steel or ruby nozzles for extended 3D printing sessions. [3][4][5]

Types and Technical Specifications

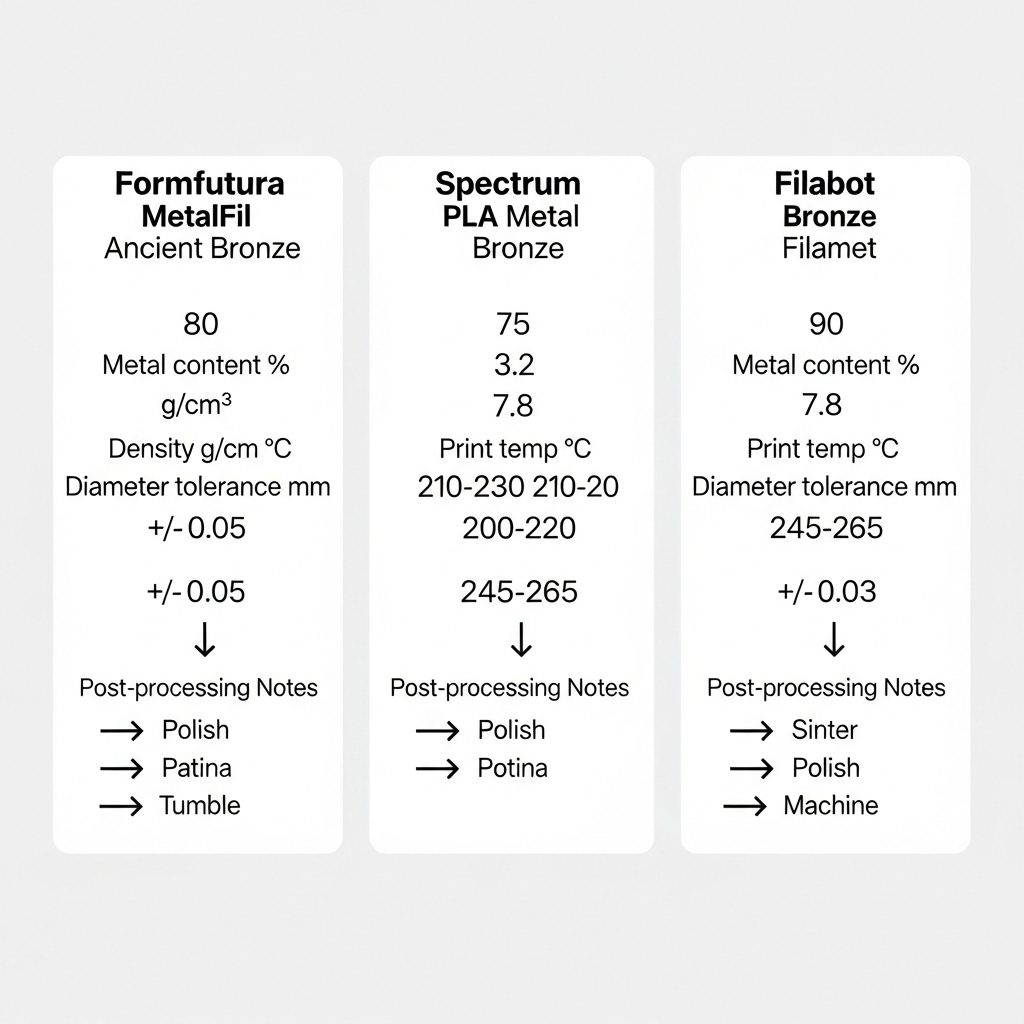

The market for metal-infused FDM filament features a range of products optimized for different applications and user needs. Leading examples include:

- Formfutura MetalFil Ancient Bronze: Approximately 60 % bronze by weight; density 3.5 g/cm³; emphasizes both metallic luster and post-processing ease.

- Spectrum PLA Metal Bronze: Density of 2.28 g/cm³ and a precise filament diameter tolerance of ± 0.03 mm—ideal for desktop 3D printers requiring consistent feed.

- Filabot Bronze Filamet: Exceptional metal loading at 88–90 % bronze, achieving densities between 4.29 and 4.5 g/cc; primarily intended for sinterable parts or high-density effects. [1][2][3][4][7]

Common print temperature ranges for these filaments are typically between 190 °C and 230 °C, although specific optimal settings vary among brands. Post-processing options include polishing to expose more metallic surface, chemical patination for aged effects, and, for highly metal-loaded filaments like Filamet, the possibility of debinding and sintering to achieve mostly metal objects.

Comparison Table: Representative Metal-Infused Filaments

| Product | Metal Content (% by weight) | Density (g/cm³) | Diameter Tolerance (mm) | Print Temp. (°C, typical) | Post-Processing Notes |

|---|---|---|---|---|---|

| Formfutura MetalFil Bronze | ~60 | 3.5 | no reliable figure found | 190–220 | Polish, patina |

| Spectrum PLA Metal Bronze | no reliable figure found | 2.28 | ± 0.03 | 190–230 | Polish, patina |

| Filabot Bronze Filamet | 88–90 | 4.29–4.5 | no reliable figure found | 190–210 | Sinter, polish |

Performance

In mechanical terms, metal-filled PLA filaments offer intermediate strength and toughness relative to pure polymers and sintered metal parts. Independent testing of MetalFil Ancient Bronze reports a tensile strength of 19 MPa per ISO 527 methodology, while Izod impact testing (unnotched, 23 °C) yields a toughness of 11.3 kJ/m². These values, while high for a composite FDM material, remain substantially below those of solid or fully sintered bronze, limiting functional load-bearing applications. [5][6]

Post-processing is a hallmark of bronze PLA. Users can polish the prints to reveal a metallic sheen, apply patina solutions for antique effects, or—in the case of high metal content variants—use sintering ovens to remove polymer binder and yield parts comprised mostly of metal, though this requires specialized equipment. [1][7][8]

Applications

Metal infused filament is most commonly used for decorative and artistic objects, such as jewelry, figurines, and sculpture. Its high density and luster simulate real metal, making it attractive for prototyping, display models, and custom design work. [1][3]

Research Updates

A peer-reviewed study published by MDPI investigated the compressive properties of 3D printed bronze PLA, revealing an elastic deformation regime sustaining loads up to 3,000 N before permanent deformation occurs. This contextualizes the material’s utility for ornamental and light structural parts, while acknowledging the inherent limits of the polymer-metal composite matrix. Recent research by commercial and academic partners—including ongoing BASF Ultrafuse studies—focuses on improving sintering quality and mechanical performance in high-metal-load filaments, suggesting a future of more robust, functional FDM-produced metal components. [5][6][10]

Frequently Asked Questions

What is metal infused filament and how does it differ from standard PLA?

Metal infused filament is a composite material made by blending standard PLA with metal powder, often ranging from 60 % (Formfutura MetalFil) to 90 % (Filabot Filamet) by weight. This results in a printable filament with metallic luster, enhanced weight, and different mechanical properties compared to standard PLA. [1][7]

How heavy is bronze PLA filament compared to standard PLA?

Spectrum PLA Metal Bronze is 2.28 g/cm³, MetalFil Ancient Bronze is 3.5 g/cm³—both are much heavier than pure PLA, which is about 1.24 g/cm³—giving a metal-like heft to 3D printed objects. [2][3]

What printing considerations are essential for metal-filled PLA?

Due to the abrasive nature of the metal powder, hardened nozzles are strongly recommended, as standard brass nozzles wear quickly. Dimension tolerance is typically ± 0.03 mm. Most manufacturers suggest printing at 190–230 °C for reliable extrusion. [4][8]

What mechanical performance can be expected from metal‑filament prints?

MetalFil Ancient Bronze achieves tensile strength of 19 MPa and impact resistance of 11.3 kJ/m², with compressive elastic behavior up to about 3,000 N. These values are substantial for composites but below those of fully metal parts. [5][6]

What differences exist between MetalFil Ancient Bronze and Filabot Bronze Filamet in metal load and sintering potential?

MetalFil Ancient Bronze contains ~60 % bronze, primarily for aesthetic and moderate mechanical use. Filabot Bronze Filamet is loaded with 88–90 % bronze and, after debinding and sintering, can yield components approaching pure metal properties. [1][7]

How does filament metal content affect nozzle wear and what nozzle options are recommended?

High metal powder content increases abrasion significantly, rapidly wearing down standard brass nozzles. Both Spectrum and HP recommend the use of hardened steel or ruby-tipped nozzles to ensure longevity when printing with metal-filled materials. [4][8]

Sources

- Formfutura MetalFil Ancient Bronze

- Formfutura MetalFil Ancient Bronze specifications

- Spectrum PLA Metal Bronze technical data

- Spectrum PLA Metal Bronze specifications

- MDPI: Characteristics of 3D Printable Bronze PLA

- MDPI: Bronze PLA mechanical testing data

- Filabot Bronze Filamet product page

- HP Learning Center: 3D Printing Metal Filaments

- Facfox: 3D Printer Metal Filament Brands

- FacFox: BASF Ultrafuse and sintering research