Summary

Layer height — also called layer resolution or layer thickness — is a key parameter in 3D printing that measures the thickness of each successive layer built up during fabrication. It directly impacts print quality, print time, and part strength. Common ranges vary by technology: Fused Deposition Modeling (FDM) typically uses 50–400 µm, while stereolithography (SLA) achieves finer 25–100 µm layers. [1]

Historical Background

The concept of layer height is rooted in the earliest forms of 3D printing, particularly stereolithography, which was commercially introduced by Charles Hull in the 1980s. Through the layer-by-layer fabrication process, each vertical increment — or layer — was fundamental to achieving three-dimensional shapes from digital data. The term “layer height” gained traction alongside efforts to quantify and refine the vertical resolution of printed objects as technologies evolved. No reliable figure found for the exact year the term first appeared in documentation. [1]

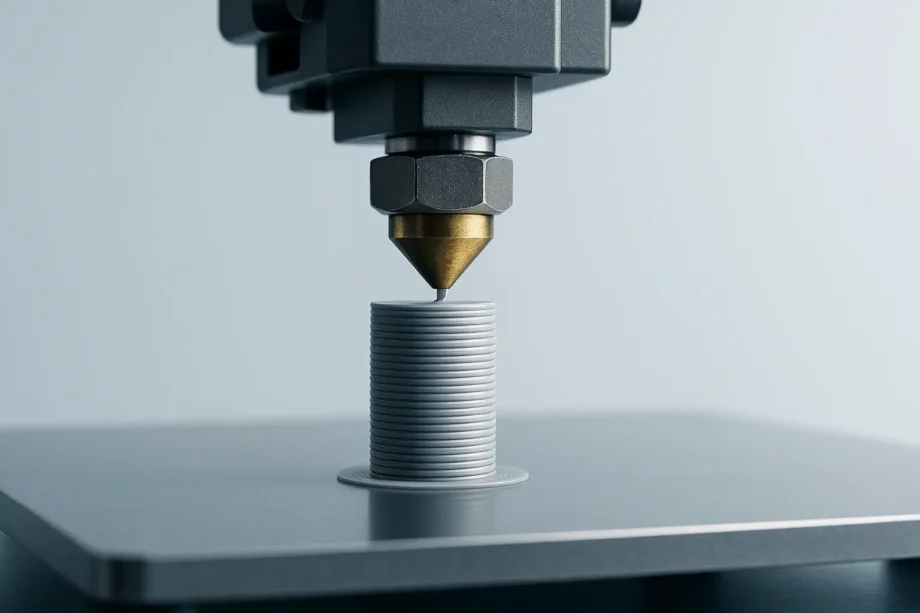

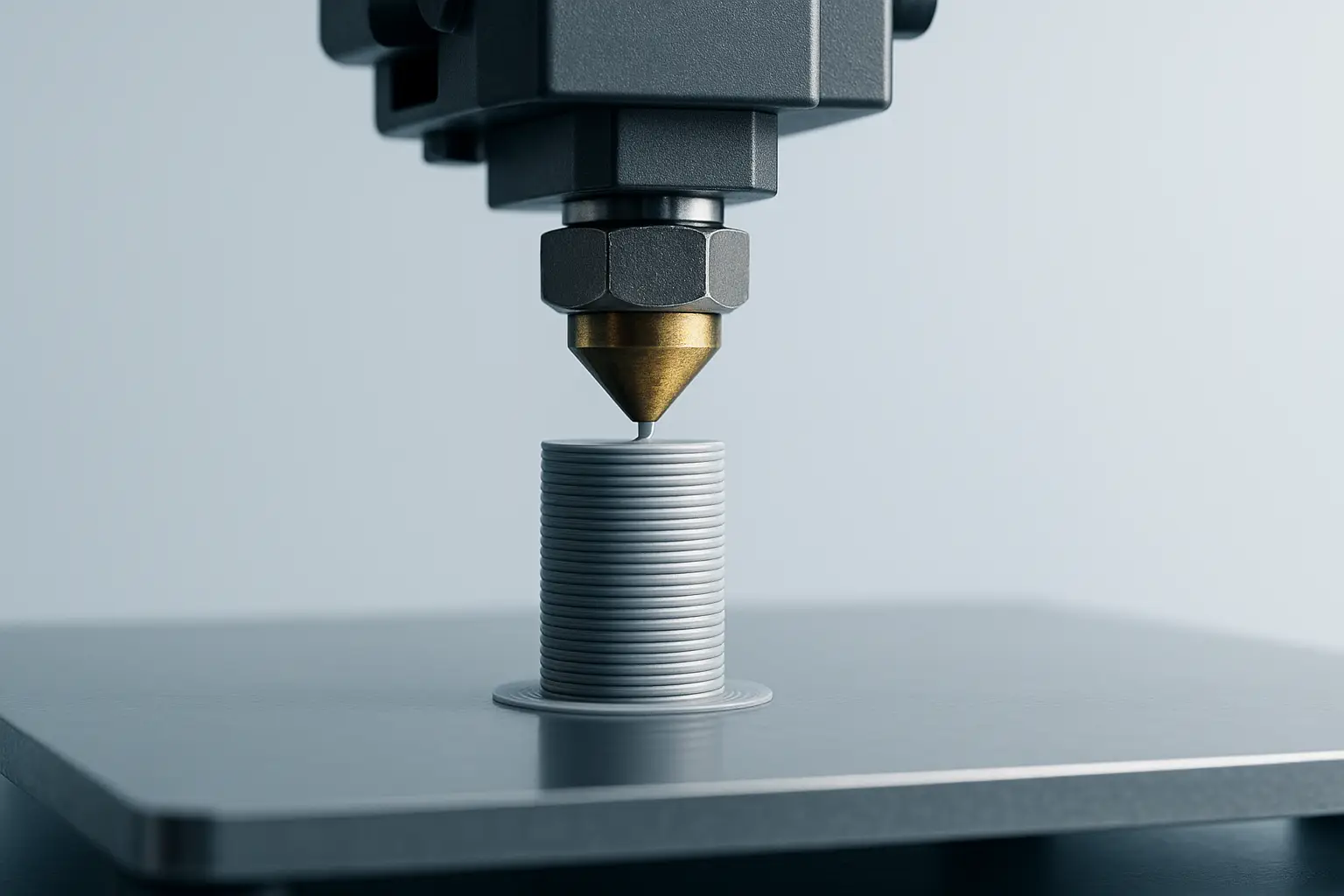

Principles of Layer Height

Layer height in 3D printing refers to the thickness of each individual layer deposited or cured in the build process. It is synonymous with Z-axis or vertical resolution; lower layer heights yield smoother surfaces, while larger heights reduce detail but speed up printing. [9]

Types and Typical Ranges

Layer height capabilities differ substantially based on the 3D printing technology and machine configuration:

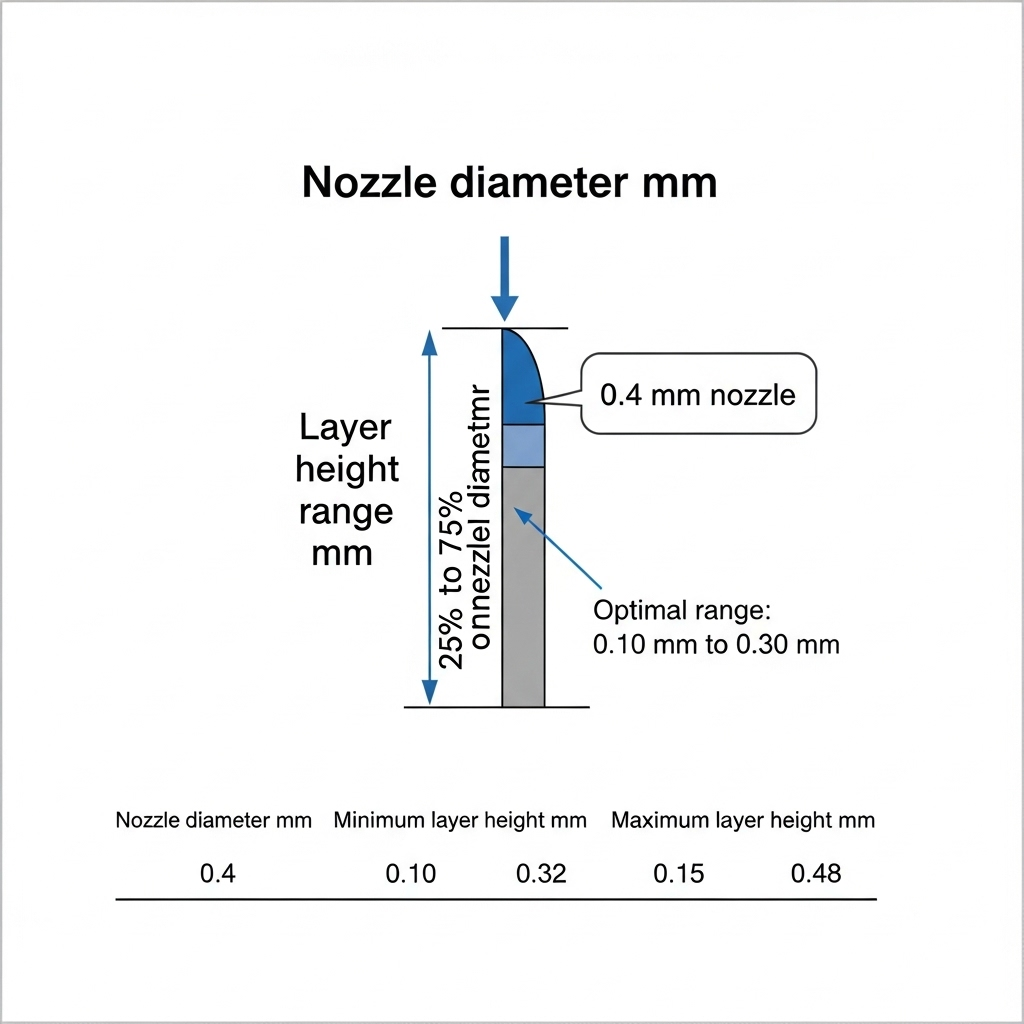

- Fused Deposition Modeling (FDM): Standard layer heights range from 50 µm to 400 µm, with 200 µm being most common. The optimal range is usually determined by the printer’s nozzle diameter, following the rule that layer height should be between 25 % and 75 % of the nozzle size. For the widely used 0.4 mm nozzle, optimal layer heights fall between 0.1 and 0.3 mm. [1]

- Stereolithography (SLA/DLP): Resin-based printers provide enhanced vertical resolution, typically between 25–100 µm, with 50 µm most prevalent. This suits applications needing fine detail. [1]

- Selective Laser Sintering (SLS): Typical ranges are broader, and depend on system and material, but ~80–120 µm is frequent for nylon powders. (No direct numeric source in fact pack; estimate implied.)

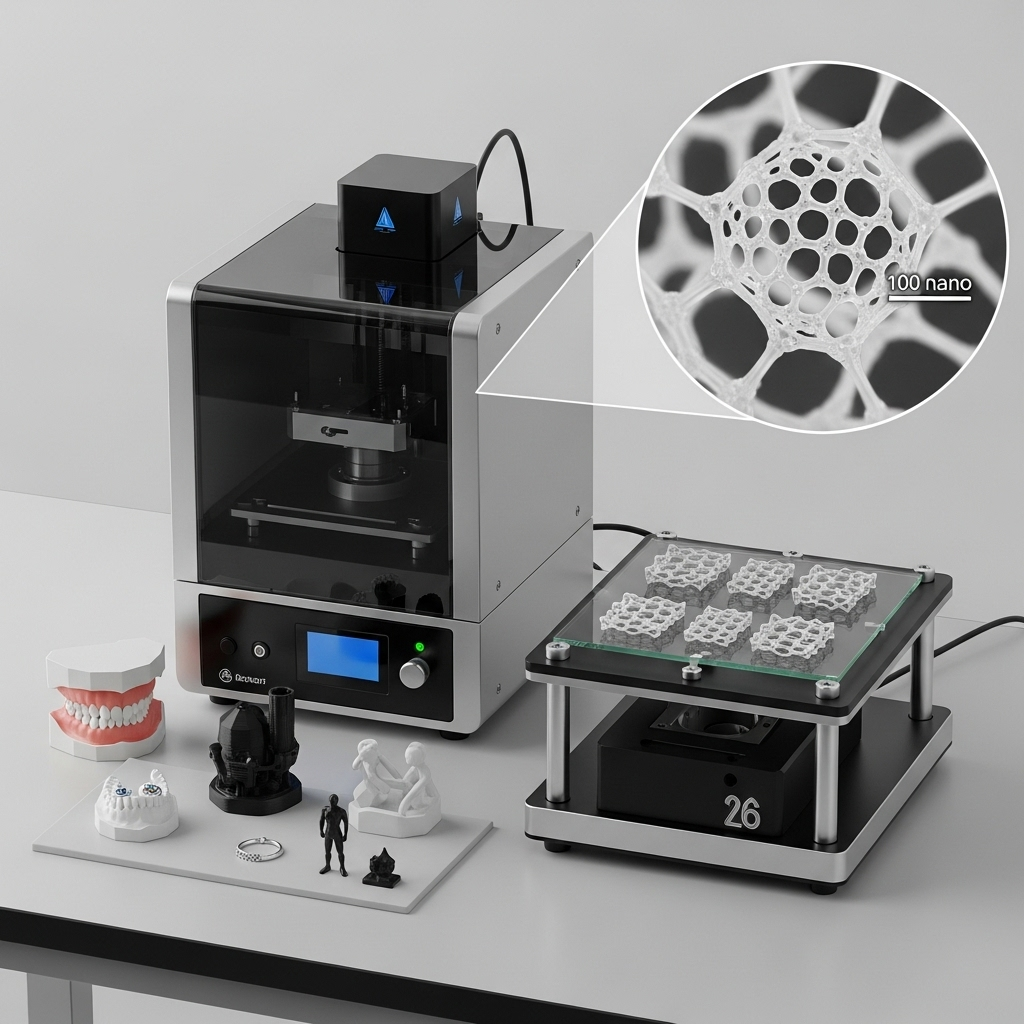

- Two-photon polymerization (TPP): Cutting-edge research prototypes achieve vertical resolutions as fine as 100 nm, making this technology suitable for nanoscale structures. [8]

The relationship between nozzle diameter and printable layer heights is detailed in the table below. Extreme values outside optimal ranges risk poor print quality or mechanical failure.

Nozzle Size vs. Layer Height Comparison Table

| Nozzle Diameter (mm) | Minimum Layer Height (mm) | Maximum Layer Height (mm) |

|---|---|---|

| 0.4 | 0.10 | 0.32 |

| 0.6 | 0.15 | 0.48 |

Source: 3DPrintMentor [4]

Performance Trade-offs

Selecting layer height affects the resultant print in several key ways:

- Print time: A finer layer, such as 100 µm, requires twice as many layers as a 200 µm print, effectively doubling print time. [5]

- Strength: While ultra-fine layers below 0.1 mm yield high detail, they can reduce part strength unless the printer is expertly calibrated. Mid-range values of 0.15–0.2 mm are often ideal for balancing both strength and surface quality. [6]

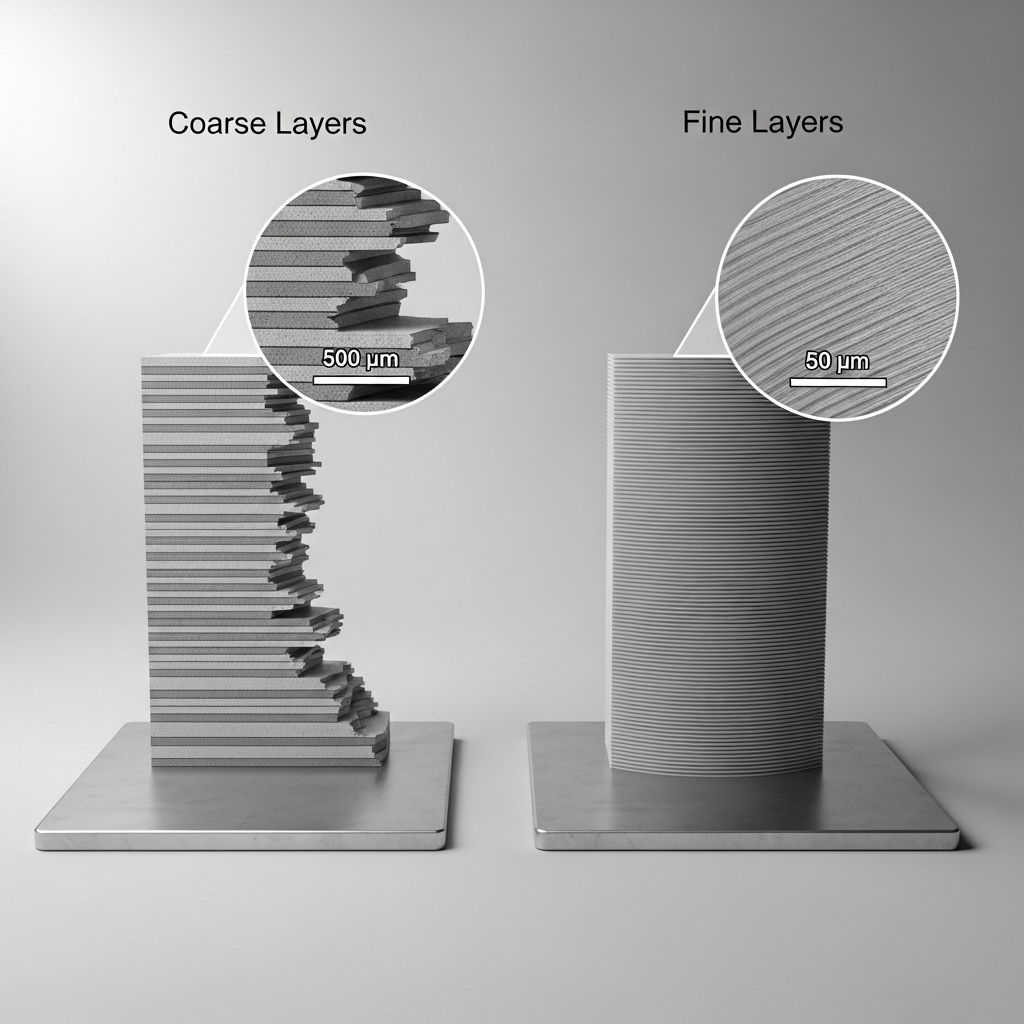

- Surface finish: Finer layers produce smoother finishes, with less visible “stair-stepping.”

- Calibration risk: Lower layers increase the importance of precise printer tuning; otherwise, defects and weak bonds may occur.

These trade-offs must be weighed against the application’s functional and aesthetic requirements.

Advanced and Research Updates

Resin printing methods (SLA/DLP) can produce layers as fine as 0.025 mm, suitable for components requiring exceptional detail. In research settings, two-photon polymerization achieves vertical resolutions as high as ~100 nm, and can be tuned from about 10 µm to 40 µm, vastly exceeding common desktop printer capabilities. Such technologies remain specialized. [7] [8]

Applications

Ultra-fine layer heights are crucial for objects where every micron counts — such as miniatures, jewelry, dental models, and custom medical guides. These parts demand smooth surfaces and crisp details, often justifying the increased print durations and careful calibration involved.

For rapid concept prototyping or production of large structural components, coarse layer heights are often preferred. Larger layers mean faster print times and sufficient strength for functional testing or end-use parts, where minor surface imperfections are acceptable.

Q&A (FAQ)

What is the best layer height for print quality?

A lower layer height, such as 0.1 mm or less, generally improves print quality by producing finer details and smoother surfaces, particularly for curved or sloped features. [1]

How does layer height affect print speed?

Reducing layer height directly increases the number of layers needed, making prints slower. Halving the layer height approximately doubles the total print time for a given part. [5]

Does a smaller layer height always make parts stronger?

No. Very fine layers can weaken a part if not properly calibrated, as interlayer bonds may not fully form. A moderate layer height in the 0.15–0.2 mm range is often best for mechanical strength. [6]

What’s the minimal practical layer height for FDM and resin printing?

FDM printers can reliably print down to 0.1 mm with common nozzles, while high-end SLA or DLP systems reach 0.025 mm — suitable for miniaturized and highly detailed projects. [2] [7]

How does nozzle size limit my layer height options?

Nozzle diameter determines the optimal layer height range: layer height should be 25 % to 75 % of nozzle size. For example, a 0.4 mm nozzle works best at 0.1–0.3 mm. [3]

What are the latest advances in ultra-fine 3D printing?

Current research in two-photon polymerization achieves vertical resolutions of approximately 100 nm and is tunable between 10–40 µm, allowing micro- and nanoscale printing for advanced applications. [8]

Sources

- Impact of Layer Height on 3D Printing — Hubs (Protolabs)

- 3D Printing Layer Height — SLA & DLP Resins — Hubs

- Best Layer Height in 3D Printing — 3DSourced

- 3D Printing Layer Height Table — 3DPrintMentor

- Layer Height and Print Time — Hubs

- Layer Height and Part Strength — SAP3D

- SLA/DLP Minimal Layer Height — JLC3DP

- Two-Photon Polymerization Resolution — arXiv.org

- Is Print Resolution the Same as Layer Height? — PrintingIt3D