Summary

Laser 3D scanners encompass triangulation, time‑of‑flight, and phase‑shift technologies — each offering a balance between accuracy and range. Triangulation models, such as the Artec Point, achieve up to 0.02 mm precision, while time‑of‑flight systems scan areas up to 1,000 m with millimetre-level accuracy. Phase‑shift scanners combine high speed and mid-range accuracy for large-scale measurements. [1][2][3]

Historical Background

Laser triangulation scanning was first developed for industrial dimensional inspection in the late 1980s, allowing manufacturers to digitize parts with high geometric accuracy — though exact patents or inventor documentation is unavailable in the core references; no reliable figure found. Time‑of‑flight (ToF) scanners have their roots in early LiDAR (Light Detection and Ranging) technology, which was pioneered for atmospheric and topographical studies by NASA in the 1960s; yet again, direct inventor identification is lacking in available overviews — no reliable figure found. Throughout the 1990s and 2000s, advancements in lasers, photodetectors, and embedded computing expanded laser 3D scanner adoption across engineering, surveying, and research. [1][2]

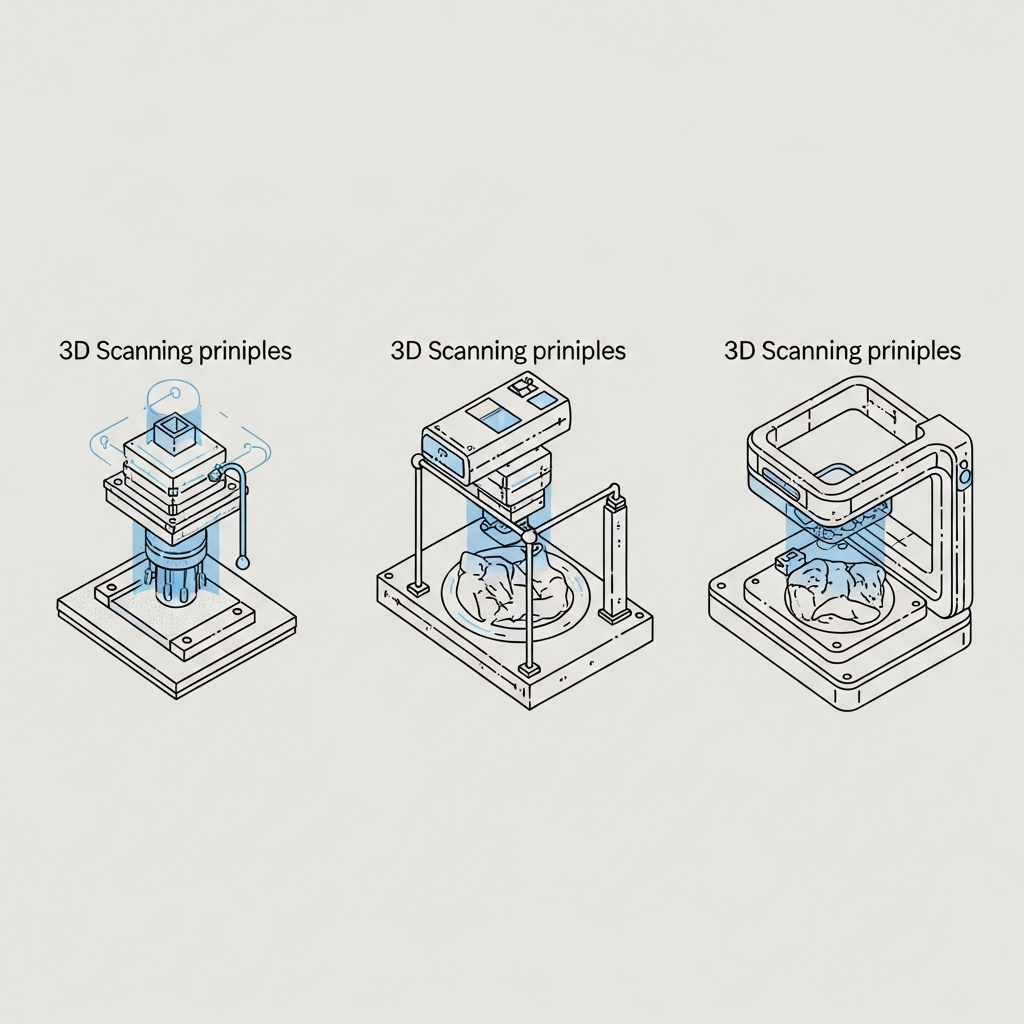

Principles of Operation

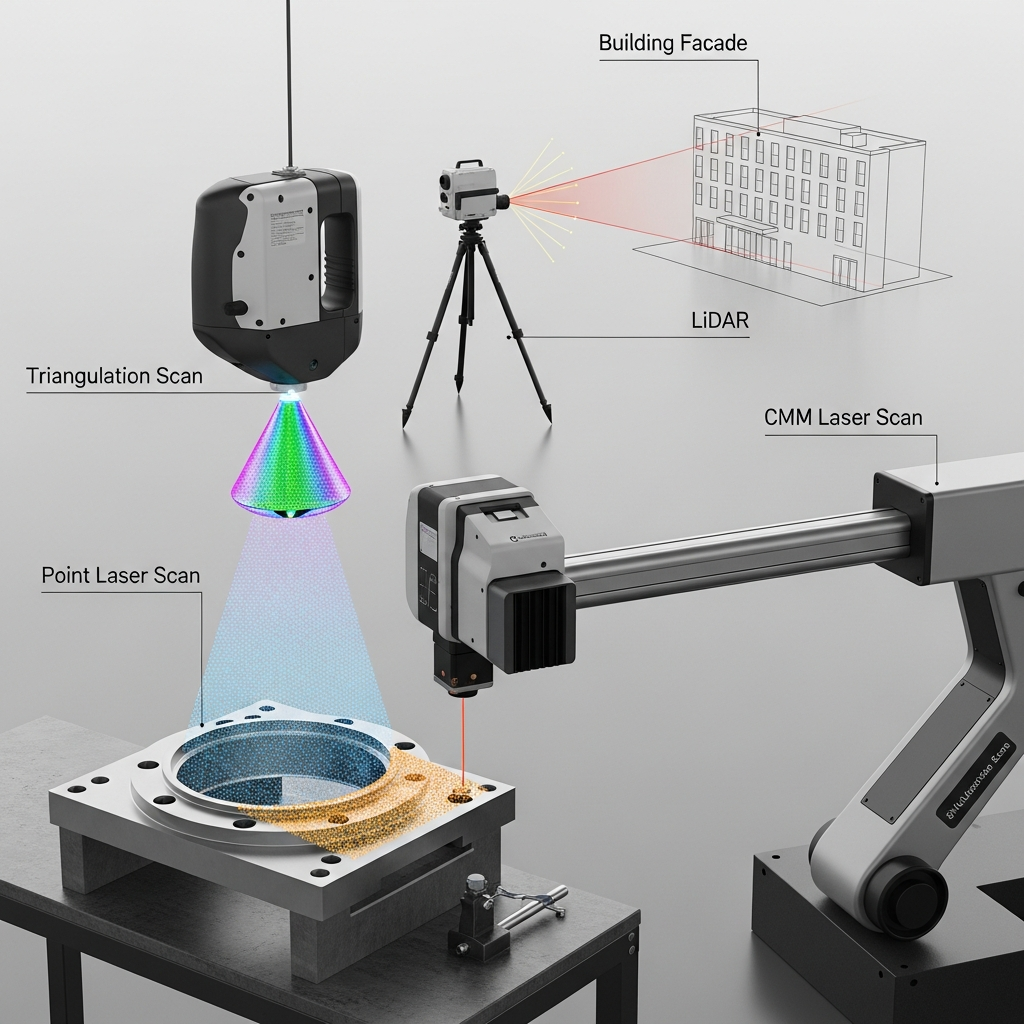

Laser 3D scanners operate based on three principles: laser triangulation, which uses geometric triangulation for high-precision measurement; time‑of‑flight, which measures light’s travel time to determine distances; and phase‑shift scanning, which calculates phase changes in a modulated laser to gauge position. [1]

Triangulation exploits the known positions of the laser source, sensor, and scanned object to pinpoint location with the greatest accuracy, suitable for smaller-scale or handheld scanning. Time-of-flight systems emit and receive laser pulses, computing the time difference to yield distance, trading some accuracy for extreme range and speed. Phase‑shift scanners instead project a continuously modulated beam and deduce displacement from measured phase differences, achieving high speed and intermediate accuracy. Triangulation excels for part inspection and small components, while phase‑shift and ToF dominate large-scale architectural, civil, and geospatial deployments. As shown by Measure Gadget, the trade-offs are clear: ToF scanners offer range (up to 6 km), but phase‑shift wins on fine accuracy and point density per second. [1][3]

Types of Scanners

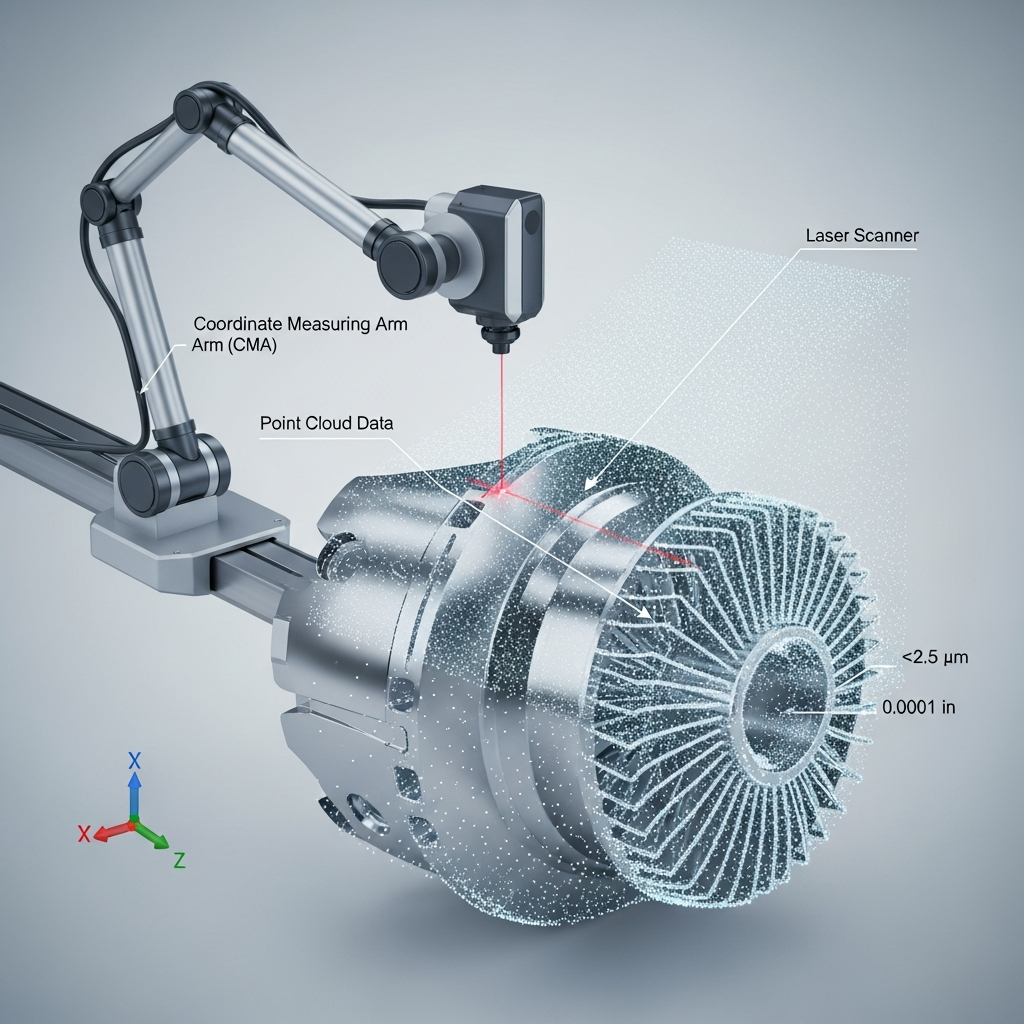

Handheld laser 3D scanners use triangulation to capture fine surface details on objects and are designed for portability; the Artec Point, for example, delivers up to 0.02 mm accuracy and up to 2.8 million measurements per second, making it ideal for industrial inspection and reverse engineering. In contrast, terrestrial and mobile platforms favor LiDAR (Light Detection and Ranging) principles — like the Artec Ray II, which achieves 1.9 mm point accuracy at 10 m, suitable for building and infrastructure surveys. These divergent platforms illustrate the influence of scanner layout and motion — stationary, mobile, or handheld — on achievable accuracy and throughput. [2][4]

Research systems push boundaries by integrating advanced optics and multiple scanning axes. An example is the dynamic light-section scanner described on arXiv, using coordinated mirrors to capture a 1,100 mm × 1,300 mm × 650 mm volume at 0.3 mm accuracy. Such multi-galvanometer or multi-angle sensing approaches seek to combine the fine detail of triangulation with the scale of time‑of‑flight, opening applications in large-volume industrial inspection or robotics where high-precision 3D data must be acquired quickly and over extended ranges. [5]

Performance Comparison

Laser 3D scanner performance spans wide precision and speed ranges depending on the method. Triangulation-based handheld and portable models provide the highest precision, with state-of-the-art devices such as the Artec Point achieving up to 0.02 mm accuracy and resolution, and data capture speeds above 2.8 million measurements per second. High-precision arms (e.g., Hexagon RS6) yield probing form errors as low as 26 µm, collecting 1.2 million points per second, while older devices like the Romer Sigma R‑SCAN present larger errors at 44 µm and rates near 19,200 points per second. Time-of-flight scanners excel at survey scale, measuring distances up to 1,000 m with typical accuracy of 3–6 mm and recording 10,000–100,000 points per second. Long-range LiDAR, as in the Artec Ray II, achieves 1.9 mm point accuracy at 10 m. Phase‑shift systems fill the niche between, with working ranges up to 150 m, accuracy from 1–3 mm, and the ability to record over 1 million points per second. According to Measure Gadget, phase‑shift systems reach ±0.5–2 mm accuracy over 100–200 m, whereas ToF covers from ±2–5 cm over 100 m to 6 km, balancing point speed and error. Comparative metrics are summarized in the table below. [1][2][3][4][5][6][7][8]

Please include a comparison table with columns for: Scanner Type, Accuracy, Typical Range, Point Acquisition Speed, Device Examples. Reference all relevant figures directly in the table.

| Scanner Type | Accuracy | Typical Range | Point Acquisition Speed | Device Examples |

|---|---|---|---|---|

| Triangulation | Up to 0.02 mm | < 1 m | Up to 2.8 million points/s | Artec Point [1], Hexagon RS6 [6] |

| Time-of-Flight | 3–6 mm | Up to 1,000 m | 10,000 – 100,000 points/s | Artec Ray II [2], [7] |

| Phase-Shift | 1–3 mm | Up to 150 m | Over 1 million points/s | Various models [3], [5] |

Applications

Laser 3D scanners are used for a wide variety of applications. Triangulation handhelds excel in quality control, reverse engineering, and documentation of heritage artifacts. Time‑of‑flight and phase‑shift models are preferred in construction, engineering surveys, and large-area mapping, capturing architecture, excavation, or infrastructure geometry for digital twin creation and analysis. [1]

Precision-driven fields benefit from advanced implementations. Industrial metrology employs high-accuracy devices such as the RS6 laser scanner on coordinate measuring arms to measure parts and assemblies with micron-level error. Construction projects utilize mobile phase‑shift or ToF scanners for rapid site progress capture and clash detection. Current research testing, like the dynamic light-section system, advances archeological digs, robotics, and medical imaging, where custom setups push the limits of accuracy while maintaining higher speed and extended volume. [5][6]

Research Updates

Recent research highlights the extension of laser scan accuracy and range using innovative hardware and computational methods. The dynamic light-section system presented in 2024 demonstrates 0.3 mm accuracy across volumes up to 1,100 mm × 1,300 mm × 650 mm, bridging the gap between single‑point precision and large-area capture. Additionally, a 2025 arXiv paper introduces a modified spatial convolutional neural network (MSCNN) technique that corrects scanner error distributions algorithmically, promising improved 3D point accuracy without changing hardware. Such advances show that the fusion of optical design and deep learning is pivotal in expanding the application and reliability of laser 3D scanners. [5][9]

Q&A (FAQ)

1. What is the accuracy of laser 3D scanners?

The top laser triangulation scanners deliver sub-millimetre, even micrometre-range accuracy — for instance, the Artec Point achieves 0.02 mm. Time‑of‑flight models generally reach 3–6 mm, while phase‑shift scanners can offer 1–3 mm across tens to hundreds of metres. [1][2][3]

2. How does laser triangulation differ from time‑of‑flight and phase‑shift scanners?

Laser triangulation determines position by geometric angle calculations from the sensor to laser spot, making it ideal for fine-detail work. Time‑of‑flight measures elapsed time of a laser pulse, allowing far greater range but less precision. Phase‑shift scanners measure phase delay in a modulated beam for high-speed, mid-accuracy scanning. [1][3]

3. What are the typical operating ranges of each laser scan technology?

Triangulation scanners typically work at short ranges under a metre, phase‑shift units reach 100–200 m, and time‑of‑flight scanners cover up to 1,000 m (LiDAR models can extend to 6 km but at reduced accuracy). [2][3][4]

4. How many points per second can modern laser scanners capture?

Handheld triangulation units (e.g., Artec Point, RS6) capture between hundreds of thousands and several million points per second. Time‑of‑flight systems achieve 10,000–100,000 points/s, while advanced phase‑shift devices exceed 1 million points/s. [2][6][7]

5. For industrial metrology, what scanner type and model offer highest precision?

Portable triangulation scanners used with articulated arms, such as the Hexagon RS6 (probing error 26 µm), provide the highest precision for industrial quality control, outpacing handhelds and long-range devices. [6]

6. How can emerging research improve laser scan accuracy without new hardware?

Recent developments such as MSCNN-based correction algorithms process raw scan data to compensate for systematic errors, significantly enhancing 3D point accuracy using software alone — as demonstrated in the 2025 arXiv paper. [9]

Sources

- Wikipedia — 3D scanning

- Artec 3D — Laser 3D Scanning Learning Center

- Measure Gadget — Time-of-Flight vs Phase-Shift Laser Measurement

- iScano — What is 3D Laser Scanning: Complete Guide 2025

- arXiv — Dynamic Light-Section Scanner Research (2024)

- MDPI — Laser Triangulation Performance Comparison

- Artec 3D — Artec Ray II LiDAR Specifications

- arXiv — MSCNN Correction Paper (2025)