Summary

G-code for 3D printing is the standard programming language used to control the movements, temperatures, and operational parameters of 3D printers. Serving as the digital bridge between 3D models and hardware, G-code remains vital for precise fabrication, directly dictating how a printer constructs each layer. Its longevity and adaptability affirm its enduring importance in additive manufacturing workflows. [1]

Historical Background

The origins of G-code trace back to the beginnings of numerical control in the 1950s, when the Massachusetts Institute of Technology (MIT) Servomechanisms Laboratory devised one of the first machine control languages to automate milling machines. This foundational innovation culminated in the formal release of the RS-274 G-code standard in 1963, a milestone for manufacturing automation. The standard received significant revision as RS‑274‑D in 1979, refining its structure and extending its hardware compatibility. G-code’s initial purpose was to unify and simplify computer numerical control (CNC) operations—a mission that laid the foundation for its later dominance in 3D printing and digital manufacturing applications. [1][2]

Principles

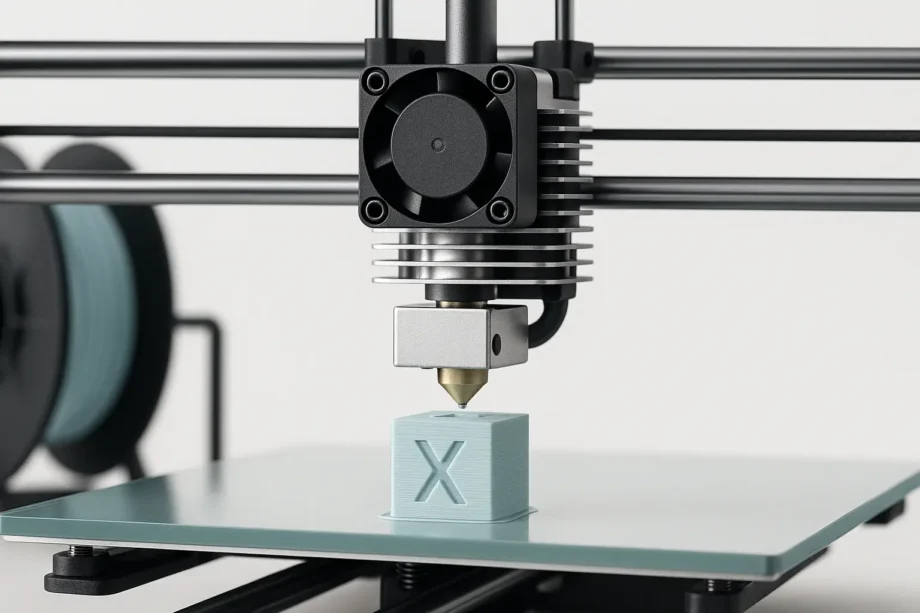

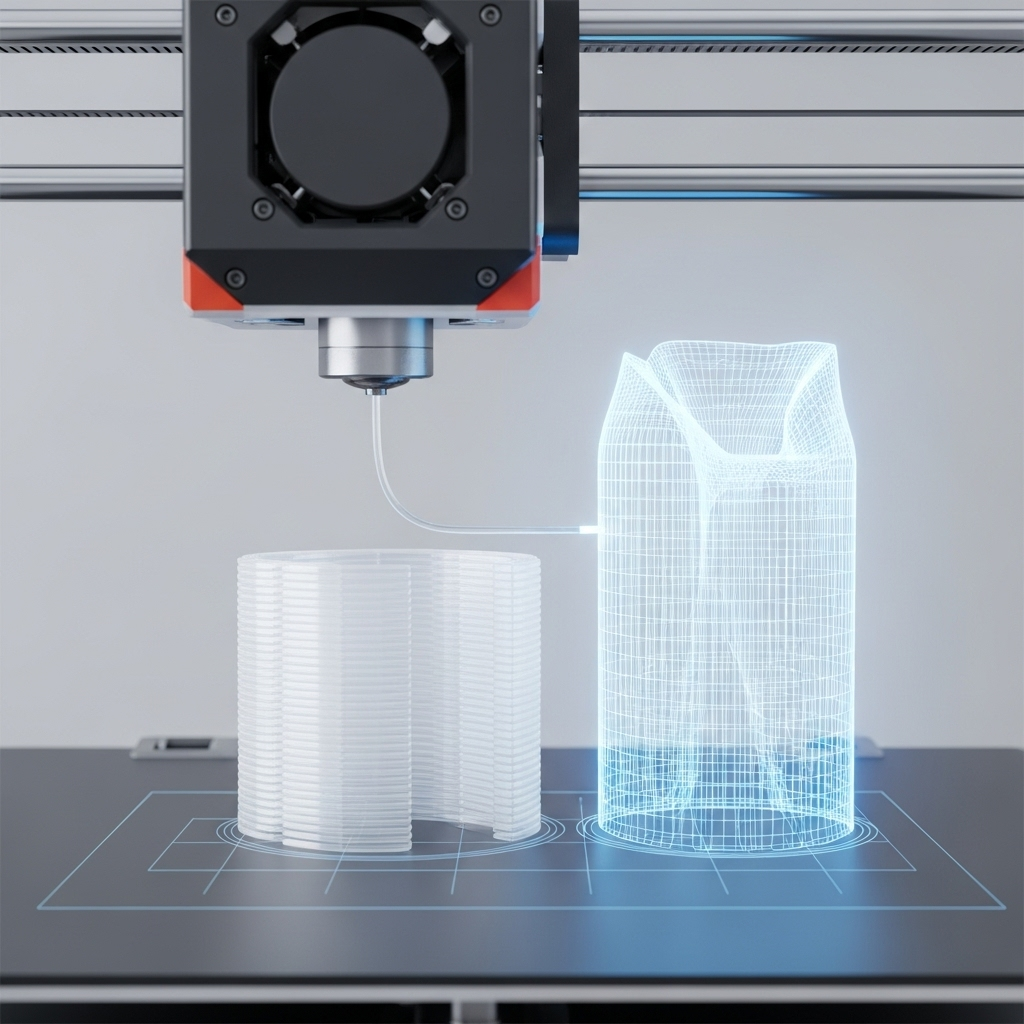

G-code is a plain-text language that encodes instructions for computer numerical control (CNC) machines and, by extension, 3D printers. It defines specific machine movements, operating speeds, and material flow rates to automatically realize complex parts. [3]

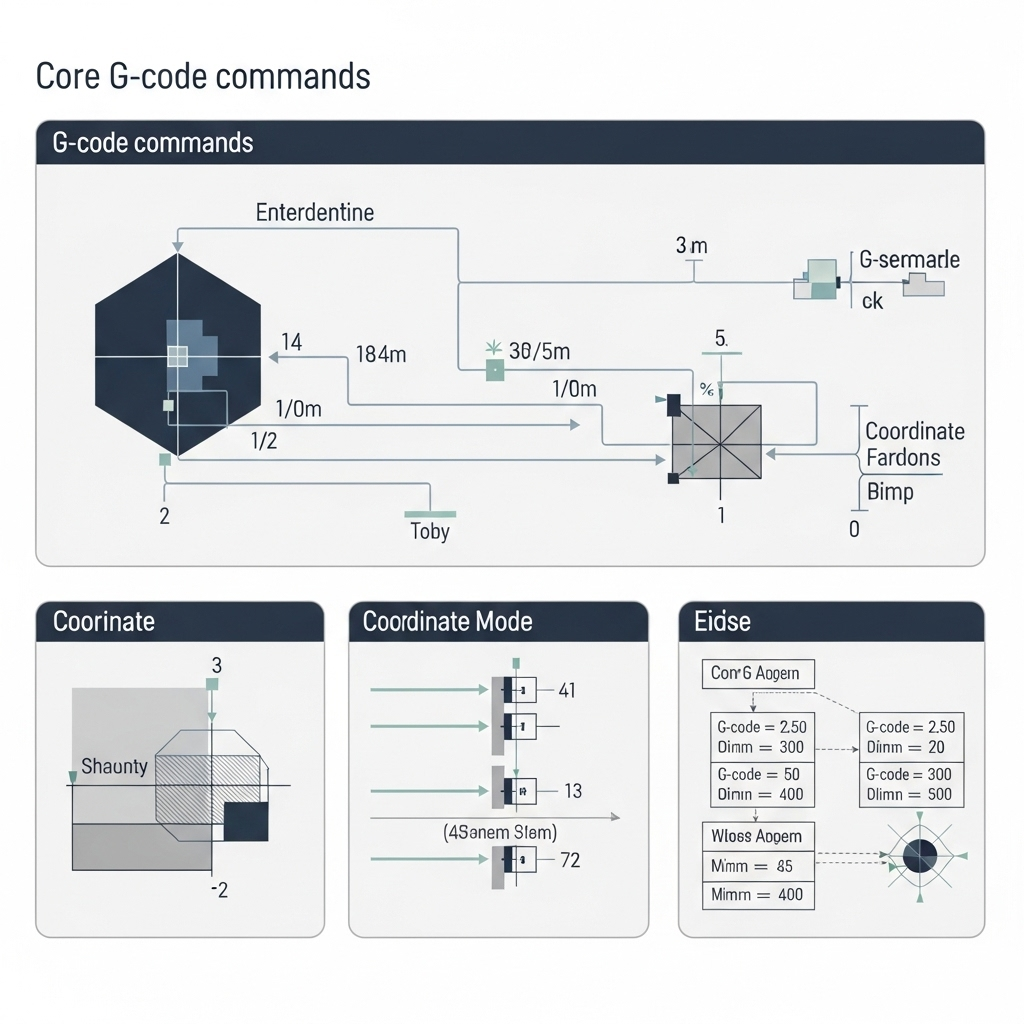

The structure of G-code includes several core elements: G-commands control motion (such as straight lines or arcs), M-commands manage machine functions (like heating or fan operations), and other commands handle coordinates, feed rates, and extrusion. In a typical additive manufacturing workflow, slicer software translates a 3D model into thousands of individual commands. The output—commonly in a .gcode file—specifies the path (X, Y, Z axes), the speed at which the print head moves, when to extrude or retract filament, and when to adjust temperatures or control the cooling fan. Slicer-generated G-code also sets whether movements are defined in absolute or relative coordinates, using commands such as G90/G91 for positioning and M82/M83 for extrusion modes. These details ensure that each layer of the print is executed with precision. [3][4][5][6]

Common G-code commands used in 3D printing:

- G1: Linear movement (print move)

- G28: Homing to origin

- G90: Set absolute positioning

- G92: Set current position

- M104: Set extruder temperature (no wait)

- M109: Set extruder temperature (wait)

- M106: Fan on

- M107: Fan off [4]

Comparison of Key G- and M-Codes

| Type | Purpose | Example |

|---|---|---|

| G | Geometric motion (move, home) | G1, G28 |

| M | Machine-specific settings/action | M104, M106 |

Coordinate Mode Comparison Table

| Mode | Command | Description |

|---|---|---|

| Absolute positioning | G90 | Positions are interpreted from a fixed zero point |

| Relative positioning | G91 | Positions are interpreted relative to last move |

| Absolute extrusion | M82 | Extruder movements are interpreted absolutely |

| Relative extrusion | M83 | Extruder movements are interpreted relatively |

Types

There are variants of G-code for 3D printing, influenced by differences in printer firmware (Marlin, RepRap, Duet, Smoothieware) and machine hardware. Additionally, slicers may specify movement and extrusion in either absolute or relative modes, using commands like G90/G91 and M82/M83 to define the operational context. These variations, largely standardized, introduce subtle differences that users should note when switching printers or slicers. [5]

Performance

G-code performance is closely tied to its ability to deliver precise machine control and accurate execution of every printed layer. It governs axis movement, heater response times, and extrusion reliability; small errors can induce defects or failed prints. Typical values for feed rate, layer height control, and time precision can vary widely across machines and firmware—no reliable figure found, as published slicer and hardware documentation present inconsistent and situational metrics. Editors are advised to consult specific slicer references for machine-verified numbers.

Recent advancements in G-code performance verification focus on reliability and systematic error detection. Differential testing, as demonstrated in the 2025 GlitchFinder study, enables automated comparison of slicer-generated G-code outputs across 58 real-world CAD models. This research highlights the power of side-by-side testing to uncover inconsistencies, bugs, and translation errors between slicer versions or machines. By enabling reproducible G-code verification, such automated tools advance the field’s understanding of reliability and help establish formal benchmarks for both slicer quality and printer performance. [7]

Applications

G-code underpins nearly all extrusion-based 3D printing applications, particularly those using fused deposition modeling (FDM) printers. It is responsible for mapping the virtual geometry of a 3D model to the precise mechanical actions required to build up each layer. Moreover, G-code’s roots in traditional CNC allow it to adapt easily for multi-head printing, multi-material workflows, and operations like temperature ramping or fan modulation. These capabilities are essential in advanced additive manufacturing contexts, including custom filament switching, progressive support strategies, complex motion planning, and hardware-level experimentation. Its command structure remains sufficiently broad to allow adaptation to new hardware and advanced workflows. [3][11]

Research Updates

The latest research, such as the GlitchFinder algorithm published on arXiv, utilizes invariant checking and differential analysis to validate slicer-generated G-code. This method not only improves reliability, but also points toward the next generation of robust, error-resistant additive manufacturing control software. [7]

Frequently Asked Questions (FAQ)

1. What is G-code 3D printing and why is it important?

G-code for 3D printing is a machine language that directs printers on how to fabricate objects layer by layer. It is crucial because it translates the 3D digital model into precise mechanical movements and controls, enabling consistent and reliable print results. [3]

2. What are the most common G-code commands in slicer output?

Some of the most used G-code commands are G1 (move), G28 (home), G90 (absolute positioning), G92 (set position), M104 (set extruder temperature), M106 (fan on), and M107 (fan off). These commands form the basis of standard print workflows. [4]

3. How does G-code syntax differ between slicers and printer firmware?

While G-code is largely standardized, differences in syntax can occur due to hardware features, custom firmware implementations, or specific printer add-ons. Slicers may generate slightly different outputs depending on target firmware like Marlin, RepRap, or Duet, especially concerning commands unique to certain printers. [5]

4. How do G90 vs G91 and M82 vs M83 affect printer movement?

G90 sets absolute positioning, causing moves to reference a fixed origin, while G91 sets moves relative to the current position. Similarly, M82 sets extruder moves as absolute, and M83 sets them as relative. The mode selected affects motion planning and extrusion accuracy. [5]

5. Can G-code generated by one slicer be compared against another?

Yes, differential testing methods like those used by GlitchFinder allow comparison of G-code outputs from different slicers for the same model. These procedures highlight divergences and help improve slicer reliability. [7]

6. What standards govern the formulation of G-code?

The formulation of G-code is principally dictated by historical standards RS‑274 (1963) and RS‑274‑D (1979), with subsequent updates and vendor-specific extensions introduced by firmware developers and printer manufacturers. [1]

Sources

- Wikipedia: G-code

- Wikipedia: History of numerical control

- Wikipedia: Fused Deposition Modeling file formats

- Fiveable: Slicing Software G-code Commands

- MDPI: G-code Modes and Performance Study

- Canion3D: Generating and Reading G-code

- arXiv: GlitchFinder Differential Testing for G-code

- Asturlayer: The History of G-code