Summary

Digital Light Processing (DLP) 3D printing, first made possible by Larry Hornbeck’s 1987 invention at Texas Instruments, was introduced to 3D printing by EnvisionTEC in 2000–2002. Compared to Stereolithography (SLA), DLP offers much faster print times (25–75 minutes vs. 90–200 minutes), achieves fine layer resolutions (5–50 μm) and clinically acceptable accuracy (<0.1 mm), and is widely deployed in dental and jewelry manufacturing. [1] [2] [3] [4]

Historical Background

The foundation of DLP printing was laid in 1987 when Larry Hornbeck at Texas Instruments invented the digital micromirror device (DMD), an innovative array of microscopic tilting mirrors to modulate projected light. [1] In the realm of additive manufacturing, DLP’s adaptation occurred more than a decade later, with EnvisionTEC producing the first functional DLP 3D printer in 2000. This breakthrough enabled the rapid layer-by-layer curing of photopolymeric resins, accelerating production times for complex objects. In 2002, EnvisionTEC introduced the Perfactory system, marking the commercial debut of DLP 3D printing, influencing key sectors such as dental, jewelry, and prototyping industries. [2]

Technical Principles

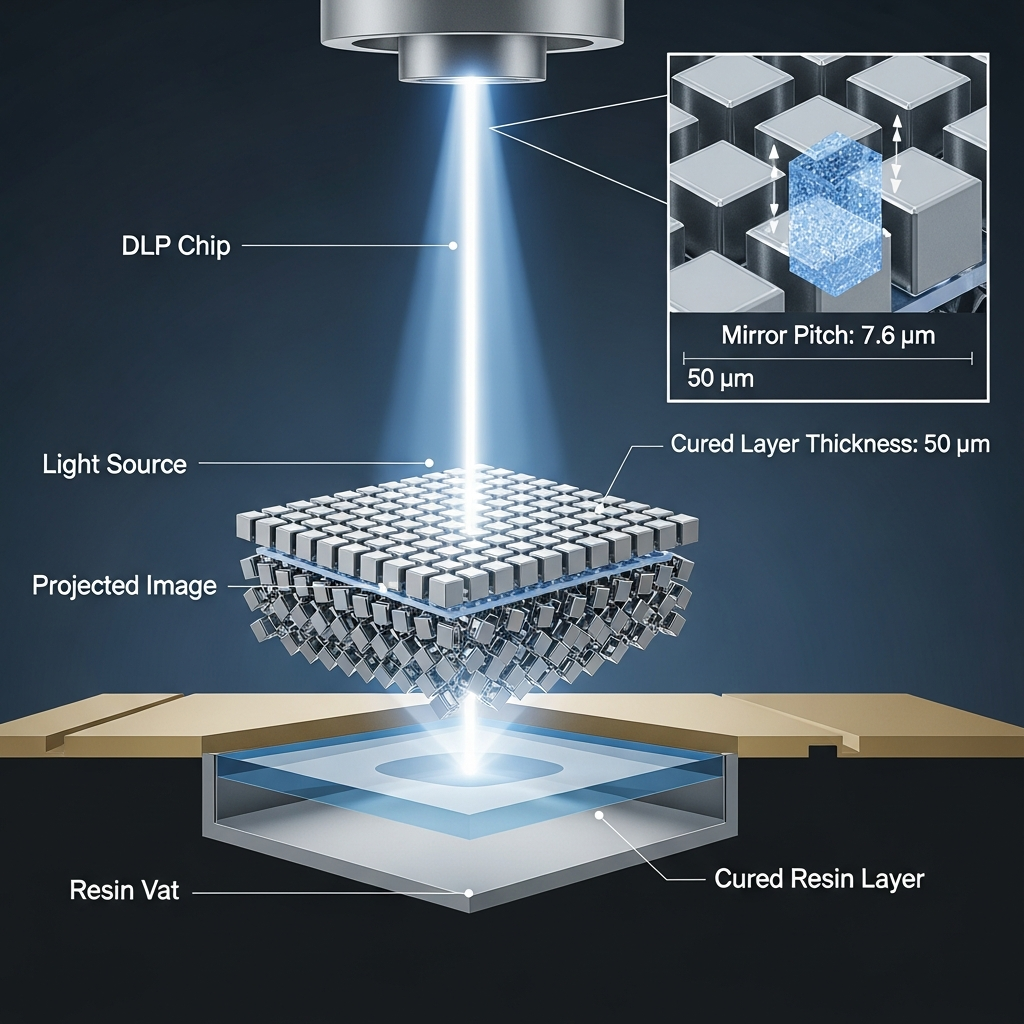

DLP printing utilizes a digital micromirror device to project entire cross-sectional layers onto a vat of resin, curing the shape in a flash, whereas SLA printing builds objects through the sequential tracing of solid boundaries with a focused laser beam. [10]

At the core of DLP’s speed is the DMD: tens or hundreds of thousands of tiny mirrors tilt to direct pixels of light, activating resin polymerization only where needed. Binary pulse-width modulation rapidly varies pixel exposure, finely controlling cure depth and detail. This all-at-once projection enables DLP to process layers in seconds rather than the point-by-point speed limitations of laser scanning in SLA. Typically, DLP achieves XY resolutions around 50 μm, though high-end units offer up to 22 μm (Anycubic Photon Ultra), and layer thickness down to 5 μm. SLA, by contrast, routinely yields 25 μm resolution on the XY-plane, with top-end machines like Formlabs Form 3+ reaching 10 μm and Z-layer thickness as low as 25 μm. [6] [7] [8] [10]

Comparison Table: DLP vs. SLA Metrics

| Metric | DLP | SLA |

|---|---|---|

| Print speed | 4–8× faster (25–75 min) | 90–200 min |

| Layer thickness | 5–100 μm (common ~50 μm) | 25–100 μm (down to 25 μm) |

| XY resolution | 50 μm typical, up to 22 μm | 25 μm typical, up to 10 μm |

| Accuracy | <0.1 mm | 0.0033–0.579 mm |

| Resin use (dental) | 9–10 mL | 5–6.5 mL |

Performance

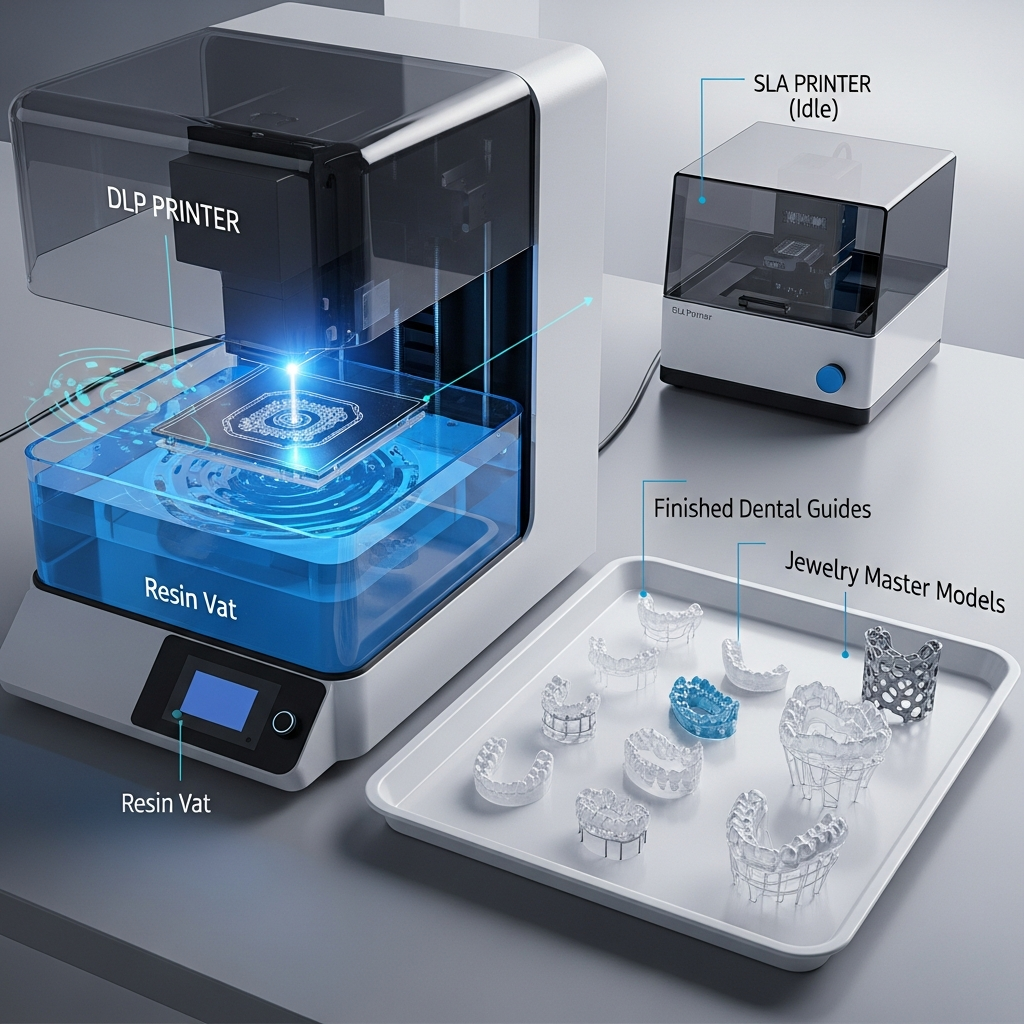

DLP delivers significant production advantages. Timing studies show dental guides printed via DLP are completed in 25–75 minutes, compared to SLA’s 90–200 minutes for the same objects. In terms of material consumption, DLP guide production averages 9–10 mL of resin, with SLA ranging from 5–6.5 mL—DLP’s efficiency is further boosted by reduced time-per-layer. [3] [9]

Accuracy analysis from published dental and medical evaluations consistently indicates that DLP achieves less than 0.1 mm mean deviation, while SLA is reported between 0.0033 mm and 0.579 mm, with the best SLA systems achieving marginally lower root mean square (RMS) errors. However, DLP sometimes produces undersized parts, a known bias, but both technologies deliver output within established clinical tolerance. [4] [5]

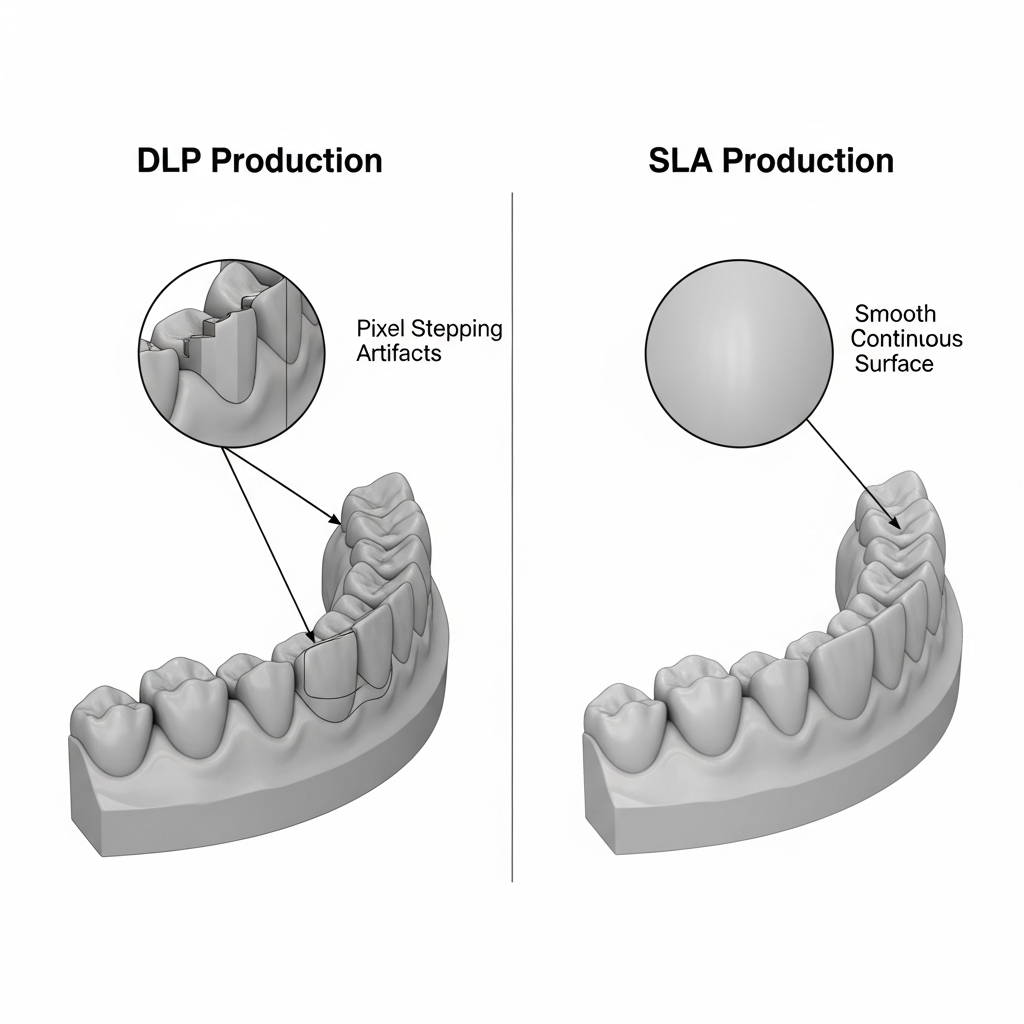

Resolution, in practical terms, governs the smallest features and smoothness of prints, determined by DLP projector pixel size (XY) and step height (Z-axis). DLP system XY resolution is typically 50 μm, with premium models achieving up to 22 μm, while SLA’s best XY performance is 10 μm (Formlabs Form 3+); standard SLA benchmarks hover at 25 μm. SLA is also notable for layer thickness as low as 25 μm; modern DLP machines can achieve minimal Z-step thickness down to 5 μm. For applications demanding fine surface detail, DLP’s speed advantage is offset only by its stepped “pixelation” artifacts—especially visible on curves—while SLA’s laser-smooth scanning reduces this effect. For example, DLP can produce a full dental guide in as little as 30 minutes (versus 4 hours for SLA), but at the cost of more apparent stair-stepping. The choice of build orientation and resolution settings can further impact both dimensional accuracy and finish. [6] [7] [8] [9]

Key DLP and SLA Performance Metrics

- Print speed: DLP outpaces SLA by 4–8× for most tasks.

- Accuracy: DLP typically <0.1 mm; SLA can reach below 0.01 mm.

- Resolution: High-end SLA and DLP now compete closely, but each has unique trade-offs depending on application.

- Material efficiency: SLA generally uses less resin for the same geometry.

Applications

Digital Light Processing is a leading technology for rapid manufacture of dental guides, crowns, aligners, and precision jewelry models—industries benefiting most from same-day turnaround. Large dental labs rely on DLP’s speed to deliver high patient throughput with multiple guides, splints, or aligners produced simultaneously, which would be impractically slow with point-scanning SLA methods. In jewelry, prototyping and short-run production of intricate masters are carried out efficiently on DLP printers. [3] [9]

Other application areas where DLP excels are quick-turn prototypes and presentation models. However, engineering use cases demanding ultra-smooth surfaces or high transparency often prefer SLA due to its reduced “pixel stepping” and consistent high optical clarity, offsetting the speed advantage. [8]

Application Industries for DLP 3D Printing

- Dental prosthetics and guides

- Jewelry models and masters

- Hearing aids and medical devices

- Prototyping (consumer, industrial, educational)

- Microfluidic and small-scale engineering parts

Research Updates

Recent research has leveraged atomic force microscopy (AFM) for in situ nanoscale characterization of DLP voxels, providing direct insight into how light-dose distributions develop during curing at unprecedented spatial resolution. Such developments support further advances in DLP speed, accuracy, and optimized exposure patterns in next-generation systems. [11]

Q&A

1. What is DLP printing?

DLP printing is an additive manufacturing method that uses a digital micromirror device (DMD)—first invented by Larry Hornbeck in 1987—to project full layers of light onto photosensitive resin. Unlike SLA, which traces boundaries with a laser, DLP flashes entire layers in a single exposure. [1] [10]

2. How does DLP compare to SLA in speed?

DLP is markedly faster than SLA, being 4–8 times quicker for most prints. Dental guides, for example, can be completed in 25–75 minutes on DLP, compared to 90–200 minutes on SLA. [3] [9]

3. What accuracy can DLP printing achieve?

DLP accuracy is typically under 0.1 mm, meeting clinical standards for dental and medical use. Some SLA systems can achieve higher (lower) RMS error, but both are well within practical requirements. [5] [4]

4. What is the typical resolution of DLP vs SLA?

Modern DLP printers achieve layer thicknesses down to 5 μm, with XY resolutions commonly 50 μm, and high-end units up to 22 μm. SLA operates at 25 μm XY natively, with premium machines achieving 10 μm and Z-layers as thin as 25 μm. [6] [7] [8]

5. Why does DLP produce pixel-like artifacts on curved surfaces?

Pixel-like “stair-stepping” occurs because a DLP’s XY resolution is dictated by the projector’s pixel size. On angled or curved geometry, this produces noticeable steps or layers, an inherent limitation of the projection approach. [9]

6. How do material consumption and orientation affect DLP guide production?

For dental guides, DLP printing uses about 9–10 mL of resin per object, regardless of orientation. This contrasts with SLA, which uses 5–6.5 mL and whose consumption may vary based on print orientation and exposure path—DLP’s speed is also less impacted by part orientation. [3]

Sources

- Wikipedia – Digital micromirror device

- AMFG – Stereolithography & Digital Light Processing: Where Are We Today?

- MDPI – Quantity of 3D Printing Resin Required for Dental Guides: SLA vs. DLP

- PubMed – Clinical adaptation of 3D printed surgical guides

- PMC – Accuracy of dental implant surgical guides

- LSRPF – SLA vs. DLP 3D Printing Comparison

- Raise3D – DLP vs. SLA 3D Printing

- Raise3D – DLP vs. SLA Industry Guide

- zone3dplus – SLA vs. DLP 3D Printing Speed Comparison

- Medium – Understanding DLP 3D Printing

- arXiv – AFM Characterization of DLP-print Voxels