Summary

CT 3D scanning, or computed tomography for internal structure scan, is a non-destructive imaging technique that captures detailed volumetric data of both internal and external geometries. Used extensively in industry and healthcare, CT 3D scanning achieves high accuracy—down to 4 µm on small parts—making it suitable for precise metrology. Unlike surface 3D scanning, acquisition can take hours, especially for dense or large objects. [1] [5]

Historical background

CT scanning originated with the work of Technicare (formerly Ohio Nuclear) in the mid-1970s, notably developing the Delta 25 and Delta 50 scanners at the Cleveland Clinic. These were among the first dual-slice whole-body and head CT scanners, capable of acquiring complete scans within 1–2 minutes—a revolutionary speed for internal medical imaging at the time. The innovation set foundational principles for modern computed tomography systems, introducing non-destructive volumetric imaging for comprehensive diagnostic and industrial purposes. [7]

Principles

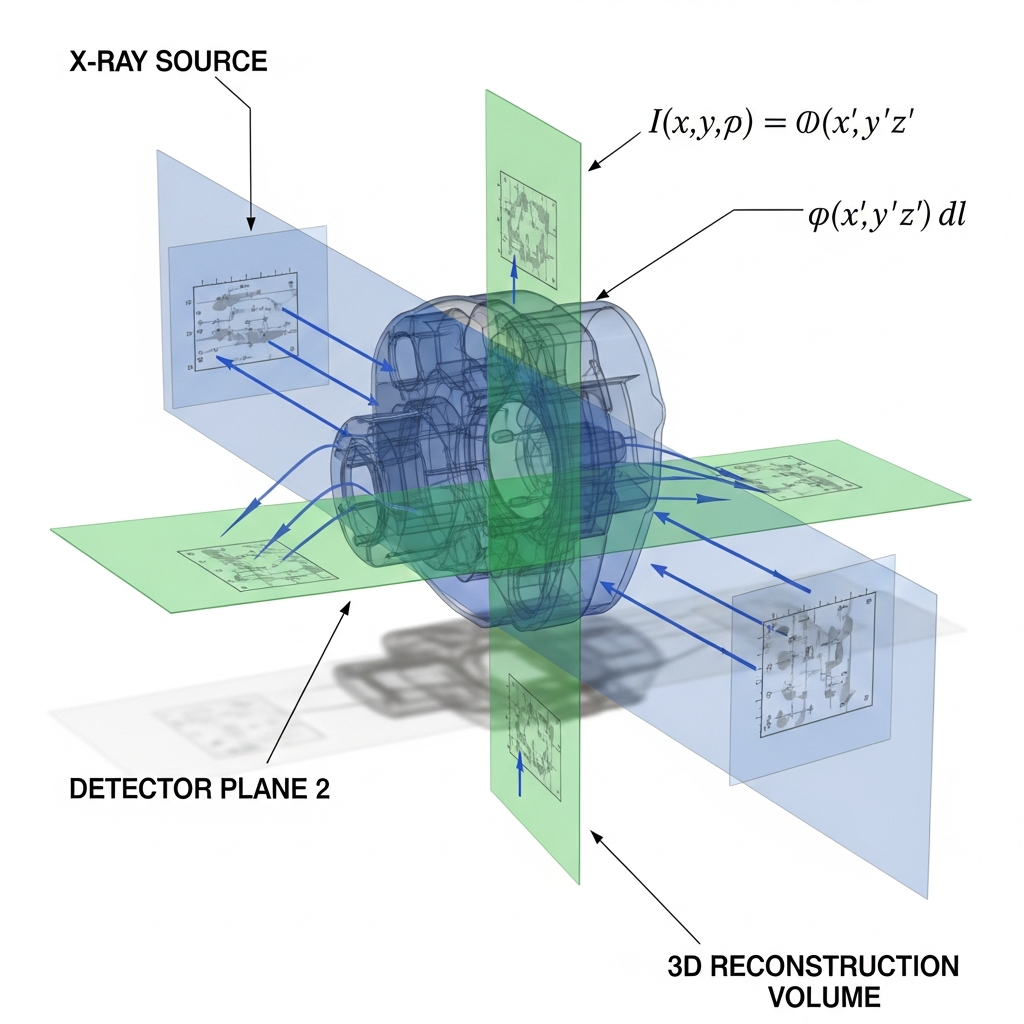

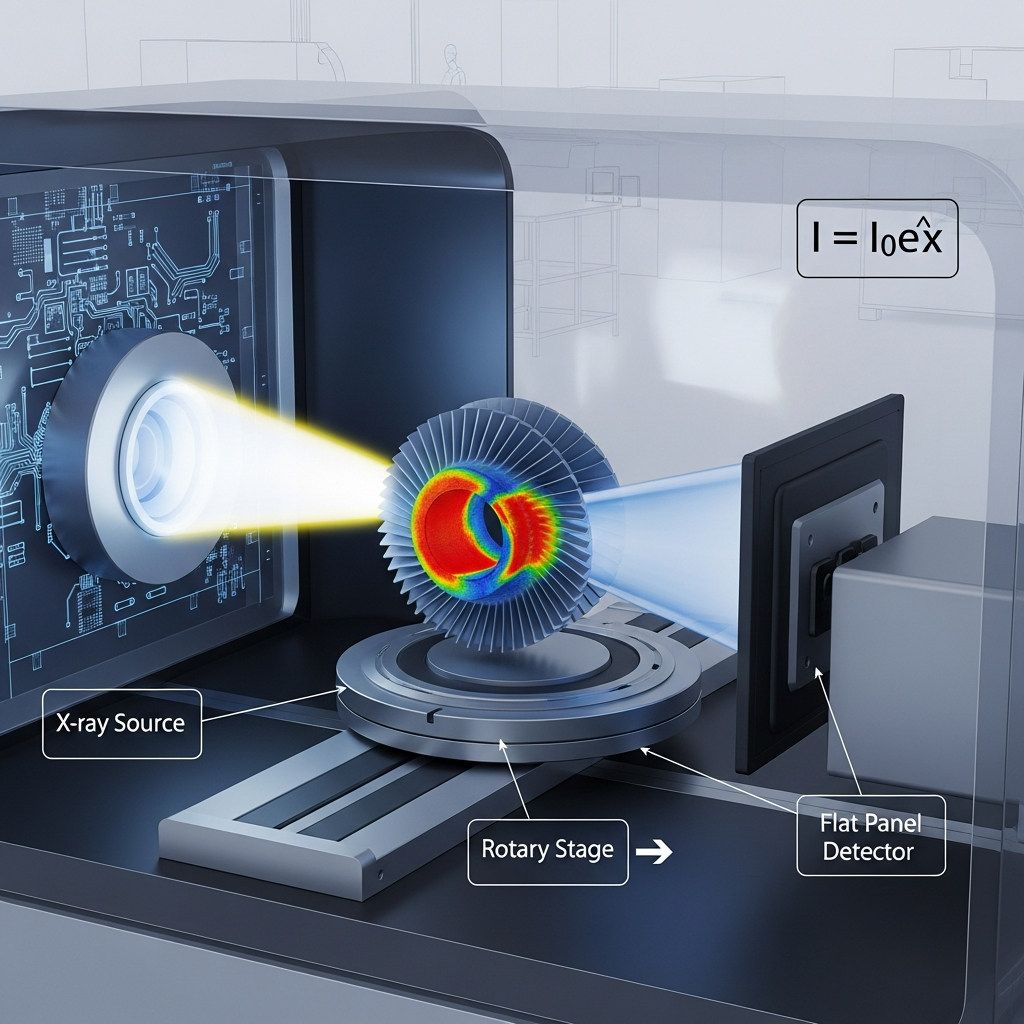

In CT 3D scanning, an x-ray source rotates around the object, capturing multiple projections from different angles. These projections are computationally reconstructed into a volumetric 3D model, providing a complete non-destructive internal and external geometry capture of the scanned subject. [4]

Technical types

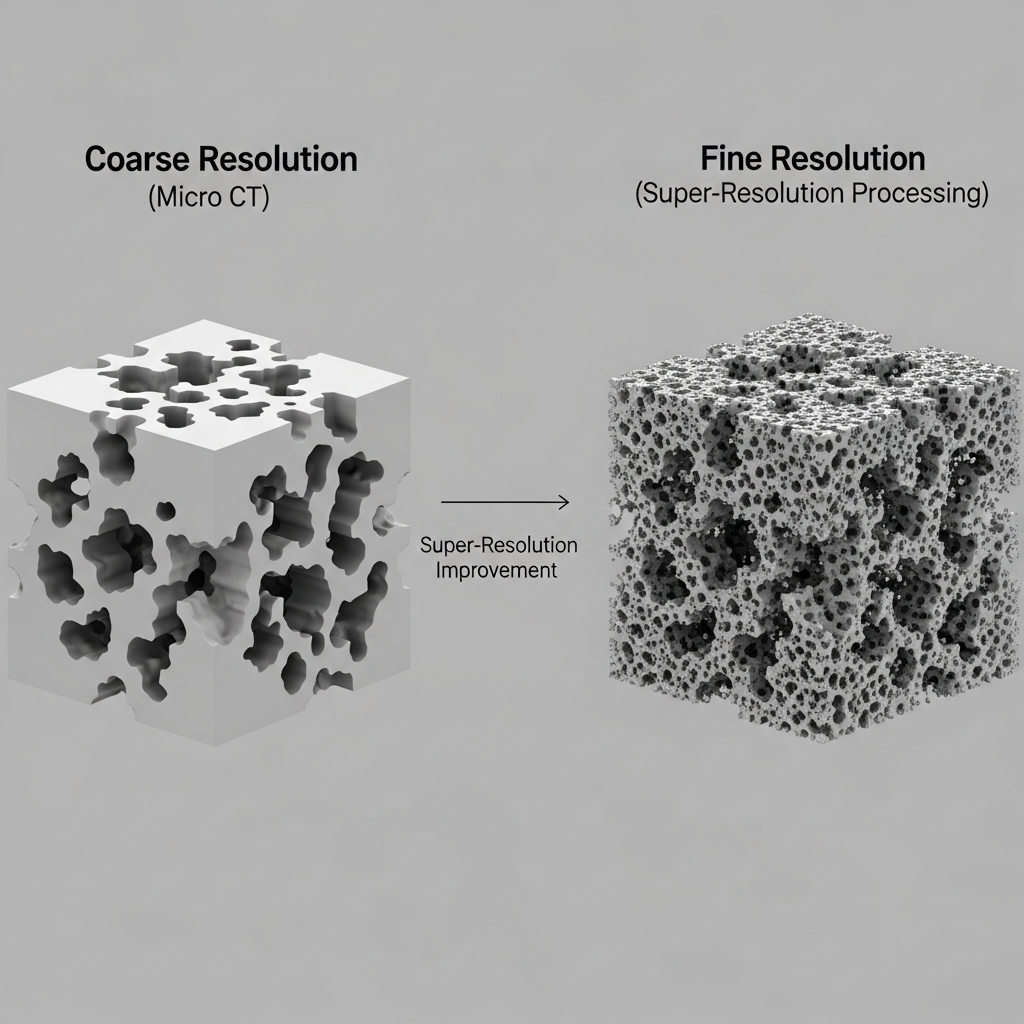

CT scanning encompasses several specialized systems, each with varying resolution, speed, and application scope. Industrial CT scanners enable metrology-grade resolutions, achieving as fine as 4 µm with accuracy to ±5 µm for small parts. [1] For medium or larger components, accuracy typically reaches ±0.010 mm to ±0.025 mm. [2] By contrast, clinical CT scanners, used for human imaging, are optimized for speed and larger volume coverage but at lower resolution. Micro-CT targets ultra-high-resolution fields, as showcased by research improving native micro-CT resolution from 7 µm to 0.44 µm using a super-resolution GAN. [6] Acquisition times also vary: Depending on part size and density, industrial CT scanning can take hours, whereas surface 3D scans are often completed in minutes. [5]

Types of CT scanners:

- Industrial CT — for metrology, defect detection, high accuracy (4–25 µm), slower speed.

- Clinical CT — for medical use, fast scanning of large volumes, lower resolution.

- Micro-CT — for research/small samples, very high resolution (sub-micrometer), low throughput.

Performance

Accuracy & resolution

State-of-the-art industrial CT scanners achieve notable precision. For small parts, metrology-grade systems from Laser Design deliver 4 µm resolution and accuracy as fine as ±5 µm. [1] For larger items or broader industrial applications, manufacturer specifications indicate ±0.010 mm on small parts and ±0.025 mm on larger components. [2] Evaluations by RX-Solutions report achievable accuracy at around 5.5 µm when benchmarked against alternative metrology methods, positioning CT 3D scanning as close to tactile or optical coordinate measurement systems for many geometries. [3] General industrial CT services report typical tolerances of 0.0005 inch (≈12.7 µm), even for larger objects, although manufacturer metrology specifications (e.g., 5.5 µm) are preferred for critical applications. [4] This range underscores the overlay between precision metrology CT systems and higher-throughput, lower-resolution industrial scanners, with the choice of system tailored to object size and accuracy requirements.

| Source | Accuracy | Resolution |

|---|---|---|

| Laser Design (small parts) | ±5 µm | 4 µm |

| Laser Design (large parts) | ±25 µm | 4 µm |

| RX-Solutions (industrial) | 5.5 µm | Not stated |

| General industrial (.0005″ claim) | ~12.7 µm | Not stated |

Speed & throughput

Industrial CT 3D scanning’s acquisition speed is intrinsically slower than surface 3D scanning: Complete internal structure scans frequently take several hours, governed by object size and x-ray attenuation, while surface-only 3D scanning typically finishes in minutes or seconds. [5]

Applications

CT 3D scanning addresses a wide range of industry and research needs. Its principal strength is non-destructive internal inspection, with applications stretching from failure analysis and porosity detection to production metrology. The high accuracy and volumetric nature of CT enable comprehensive quality assurance and engineering insight.

Typical application domains:

- Non-destructive inspection of internal geometry

- Porosity and defect analysis

- Assembly verification at the sub-component level

- Metrology and reverse engineering for complex or inaccessible features

These roles leverage the micron-level accuracy and superior internal visualization of CT 3D scanners. [1] [2]

Research updates

Recent research demonstrates a deep learning approach using an Octree-based generative adversarial network (GAN), which enhanced native micro-CT resolution from 7 µm to 0.44 µm per voxel—representing a major advance for high-resolution imaging in research and fine metrology. [6]

Frequently Asked Questions (FAQ)

1. What is the typical resolution of industrial CT 3D scanning systems?

Industrial CT 3D scanning achieves up to 4 µm resolution and ±5 µm accuracy for small parts. For larger parts, accuracy ranges from ±0.010 mm to ±0.025 mm, with independent assessments reporting approximately 5.5 µm for advanced systems. [1] [2] [3]

2. How does CT scanner accuracy compare to other metrology methods?

CT 3D scanning rivals the accuracy of tactile and optical coordinate measuring machines, especially for complex or inaccessible geometries. RX-Solutions reports accuracy nearing 5.5 µm, while typical industrial services claim 0.0005 inch (≈12.7 µm); manufacturers’ metrology specifications—such as 5.5 µm—are preferred for precision needs. [3] [4]

3. Why is CT 3D scanning slower than surface 3D scanning?

CT 3D scanning requires the acquisition of hundreds to thousands of x-ray projections and a computationally intensive volumetric reconstruction, resulting in scan times that often span hours—compared to seconds or minutes for surface-only 3D scanning. [5]

4. What types of CT scanners exist, and how do they differ?

There are industrial CT scanners for precise metrology and defect analysis, clinical CT scanners for large-volume medical imaging, and micro-CT systems targeting sub-micron research applications. They differ primarily in resolution, throughput, and volume scanning capabilities. [1] [2] [6]

5. How has micro-CT resolution been improved recently?

Recent research enhanced native micro-CT resolution from 7 µm to 0.44 µm per voxel using a super-resolution GAN, providing new capabilities for materials science and fine metrology research. [6]

6. What were early CT scanners’ capabilities and purpose?

The first dual-slice CT scanners, developed by Technicare in the mid-1970s, were designed for whole-body and head imaging and could complete scans in just 1–2 minutes—a major technological breakthrough for clinical diagnostics. [7]

Sources

- Laser Design — Nondestructive, 3D Scanning Products Overview (resolution & accuracy)

- Laser Design — CT Scanning Metrology Overview (part size constraints)

- RX-Solutions — Precise dimensional metrology with CT scanning

- 3d-scan.com — Industrial CT scanning capability & specification

- Dynamic Metrology — Internal or External? CT Scanning vs. 3D Scanning

- arXiv preprint — Super-resolution GAN for micro-CT imaging (May 24, 2025)

- Wikipedia — Technicare (history of early CT scanners)