Summary

Carbon fiber filament is a composite 3D-printing material that blends plastic polymers with carbon fibers to achieve high mechanical strength and stiffness. Typically used for engineering prototypes and functional end-use parts, this material can surpass metals in performance for certain applications due to its superior flexural and tensile properties. 1 6

Historical Background

The use of carbon fiber filament in 3D printing was pioneered by Markforged in 2014 with the launch of the Mark One printer, which enabled continuous fiber reinforcement in fused deposition modeling (FDM) parts. 10

Carbon fibers themselves were invented by Roger Bacon in 1958 at National Carbon, Cleveland, Ohio, setting the stage for future advances in composite manufacturing. 11

Technical Principles

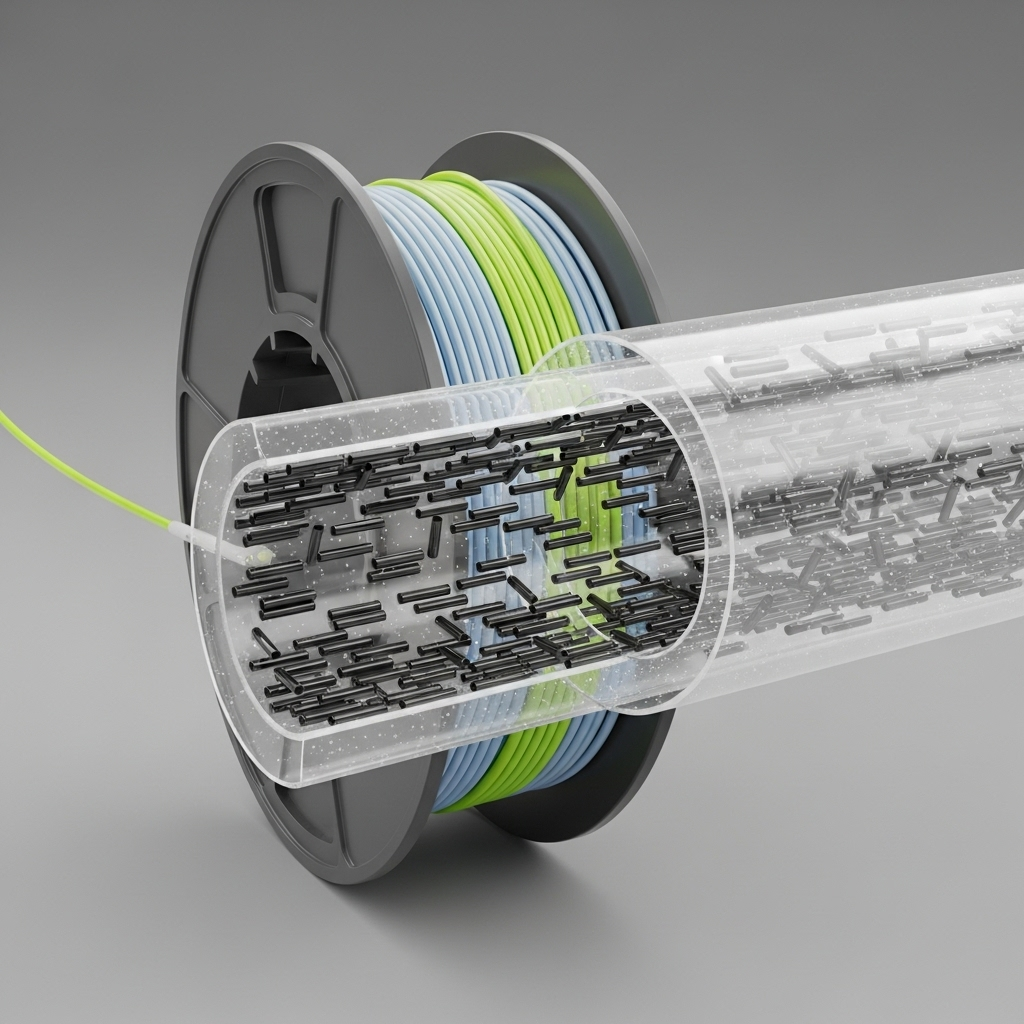

Carbon fiber filament is a composite material, typically consisting of a thermoplastic matrix — such as nylon or polylactic acid (PLA) — combined with either chopped or continuous carbon fibers. This reinforcement greatly increases material stiffness and strength, while also reducing part warping during the printing process. Chopped carbon fiber enhances tensile strength, modulus, and stiffness by as much as 115 %, 530 %, and nearly 300 % respectively, compared to unreinforced polymers. 7 The inclusion of carbon fiber also improves dimensional stability. 9 In continuous fiber composite filaments, FDM parts can achieve tensile strengths up to 1,000 MPa and flexural strengths up to 800 MPa, rivaling metals in specific contexts. 8

Types of Carbon Fiber Filament

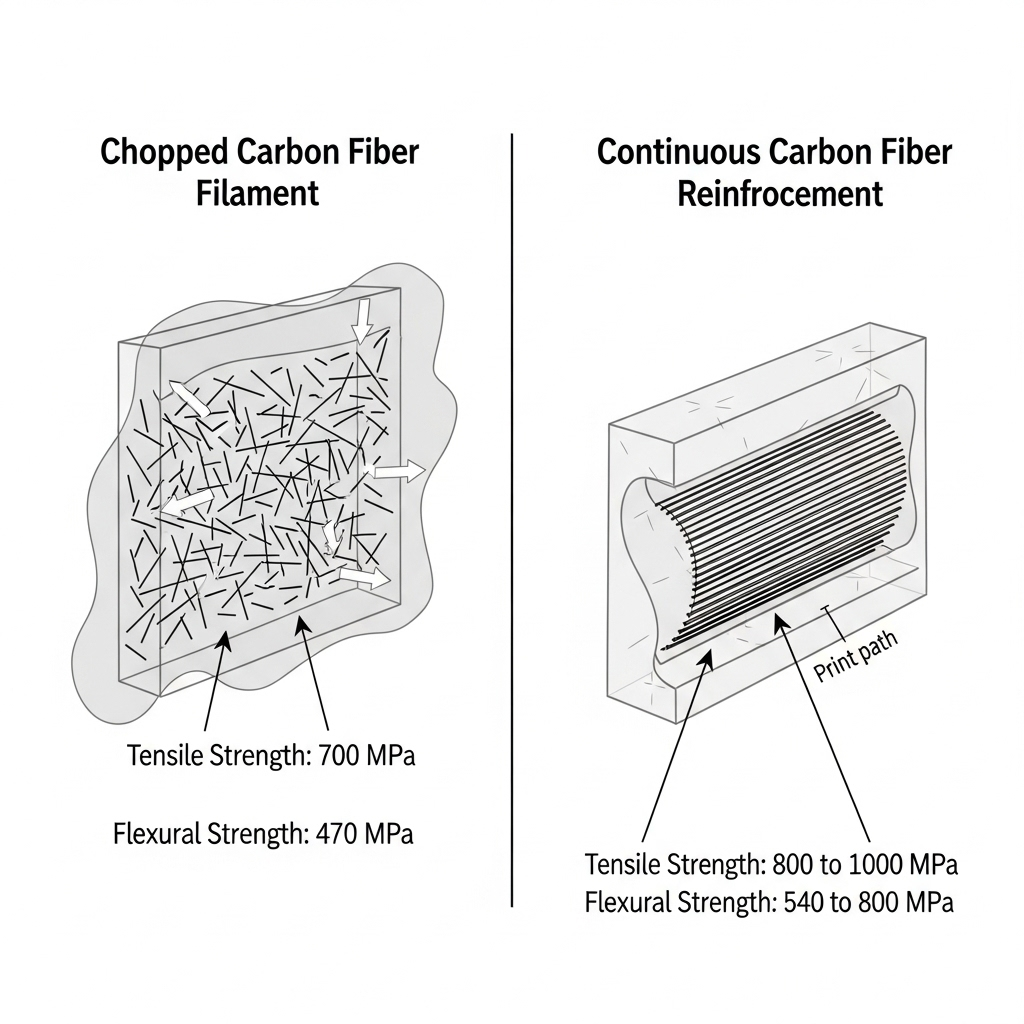

Chopped carbon fiber filament consists of a polymer filled with short, uniformly dispersed carbon fiber segments, providing a flexural strength of 470 MPa and tensile strength of up to 700 MPa. 1 2

Continuous carbon fiber reinforcement, exemplified by the Markforged platform, involves laying continuous fibers within the print for maximal load transfer, reaching flexural strengths of 540 MPa and ultimate tensile strengths up to 1,000 MPa as reported by ICT Fibers. 3 8

Laboratory research has produced advanced filaments, such as melt-impregnated PLA-based continuous fiber reinforced thermoplastics (CFRTP) with 40 % fiber fraction, achieving exceptional tensile strength (989 MPa) and flexural strength (310 MPa). 6

Performance

| Material Type | Tensile Strength (MPa) | Flexural Strength (MPa) | Tensile Modulus (GPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|

| Chopped CF filament (typical) | 700 2 | 470 1 | — | — |

| Markforged continuous CF | — | 540 3 | — | — |

| Continuous FDM CF (ICT Fibers) | 800–1,000 8 | 540–800 8 | 60–100 8 | 51–71 8 |

| PLA‐CFRTP 40 % continuous | 989 6 | 310 6 | — | — |

| Nylon 6,6/30 % CF (dogbone specimen) | 115 4 | 68 5 | 7.4 4 | 1.5 5 |

| Unreinforced Nylon 6,6 (dogbone) | 84 4 | — | 1.1 4 | — |

Compared to unreinforced polymers, carbon fiber reinforced materials offer a step-change in mechanical properties. Chopped carbon fiber composites show significantly higher flexural (470 MPa) and tensile (700 MPa) strengths, while continuous fiber technologies can reach or exceed the performance of certain metals. Laboratory-scale CFRTP filaments have demonstrated ultimate tensile strengths near 1,000 MPa. 1 3 5 6 8

Printability is influenced by several factors. Carbon fiber’s rigidity suppresses warping and reduces shrinkage, enhancing dimensional accuracy during FDM printing. 9 However, carbon fiber’s abrasive nature causes rapid nozzle wear — thus, hardened steel or ruby-tipped nozzles are recommended. Process parameters, including higher print temperatures and reduced print speed, are necessary to achieve optimal layer adhesion and part integrity. Chopped carbon fiber filaments can improve part accuracy and decrease deviations, while also amplifying mechanical performance as documented by AON3D, which reports increases of up to 115 % in tensile strength and 530 % in modulus. 7

Applications

Carbon fiber filament serves in diverse sectors, notably where a high strength-to-weight ratio and dimensional stability are paramount. Typical application domains include:

- Aerospace (drones, brackets, covers, interior structural parts)

- Automotive (fixtures, lightweight brackets, functional prototypes)

- Industrial tooling and manufacturing jigs

- Robotics (arm segments, custom grippers)

- Sporting goods and performance equipment

- End-use functional prototypes and replacement parts 1

Research Updates

Recent research in CFRTPs has yielded laboratory-printed filaments with continuous 40 % carbon fiber, showing tensile strength as high as 989 MPa and flexural strength up to 310 MPa, pointing toward future advances in ultra-strong composites. 6 Additionally, field-based toolpath optimization research indicates strength increases up to 71 % by aligning carbon fibers to operational load vectors. 12

Ongoing challenges persist in controlling layer adhesion and preventing defects in 3D-printed composites. Studies published in the Journal of Polymer Science note that even with 30 % carbon fiber content, processing parameters heavily influence tensile and flexural performance, and continued progress is needed to resolve print-induced weaknesses. 4 5

Q&A (FAQ)

1. What makes carbon fiber filament stronger than standard 3D-printing plastics?

Chopped carbon fiber reinforced filament exhibits a flexural strength of 470 MPa — eight times stronger than ABS — and achieves tensile strengths up to 700 MPa, more than twice that of aluminum, due to the reinforcing effect of short carbon fibers distributed throughout the polymer matrix. 1 2

2. How does continuous fiber reinforcement compare to chopped fiber in strength?

Continuous fiber systems, such as Markforged’s, deliver flexural strengths up to 540 MPa and ultimate tensile strengths between 800–1,000 MPa, significantly outperforming chopped fiber filaments. 3 8

3. What are the highest tensile strength values achieved in research for carbon fiber filaments?

Experimental CFRTP filaments with 40 % continuous carbon fiber content achieve tensile strengths up to 989 MPa, which currently stands among the highest reported values for 3D-printed polymer composites. 6

4. Why does carbon fiber filament reduce warping during printing?

The presence of carbon fibers increases the composite’s rigidity and dimensional stability, suppressing shrinkage and reducing warping that is commonly observed in pure thermoplastics. 9

5. What challenges arise when printing with carbon fiber reinforced filaments?

Carbon fibers are highly abrasive and rapidly wear down standard brass nozzles; thus, hardened nozzles are recommended. The increased material stiffness can also make parts more brittle, and optimal results require higher print temperatures and careful process control. 9

6. How does fiber fraction and processing affect mechanical properties?

Incorporating 30 wt % carbon fiber within Nylon 6,6 improves tensile strength to 115 MPa and flexural strength to 68 MPa, compared to 84 MPa for unreinforced nylon. Increasing the fiber fraction, as in CFRTPs with 40 %, elevates tensile properties to 989 MPa, illustrating the critical link between fiber content, processing, and ultimate part strength. 4 5 6

Sources

- GSC–3D Carbon Fiber Filament Material Page

- iPrint3D: Carbon Fiber Filament Materials

- Markforged: Continuous Carbon Fiber Materials Data

- Wiley Journal of Polymer Science: Mechanical Properties of 3D Printed Carbon Fiber Nylon

- Wiley Journal of Polymer Science: Flexural Properties of Carbon Fiber Nylon

- ScienceDirect – Additive Manufacturing: High Strength CFRTP Materials

- AON3D – Chopped Carbon Fiber Reinforced Filament Performance

- ICT Fibers: Carbon Fiber 3D Printing Guide

- Lab3D: Best Carbon Fiber Filaments Guide

- Wikipedia – Markforged Mark One (Early Carbon Fiber Printer)

- Wikipedia – History of Carbon Fibers (Roger Bacon, 1958)

- arXiv: Field-Based Toolpath Optimization for Additive Manufacturing