Summary

3D slicing is the computational process of converting a digital 3D model into a sequence of horizontal toolpaths—commonly known as G-code—that guide an additive manufacturing machine as it lays down material layer by layer. Slicing software segments models, calculates internal structures, and generates necessary supports and bases. Since open‑source milestones such as Slic3r’s launch in 2011, and with the proliferation of tools like Cura, slicing has become foundational to 3D printing. Ongoing research focuses on boosting efficiency, accuracy, and intelligent support generation. [1][2][3][4]

Historical Background

The concept of 3D slicing originates from the foundational need to translate complex digital solids into a format compatible with layer-by-layer additive fabrication. Pioneering work began in the mid- to late-1980s alongside early rapid prototyping systems that used simple planar slicing to approximate model geometry. Alessandro Ranellucci’s Slic3r project, first uploaded around 1 September 2011, became one of the earliest widely recognized open-source slicing software packages, setting a foundation for community-driven development and practical utility in desktop 3D printing. [2]

The growth of slicing as a discipline accelerated through both open-source efforts and industrial adoption. Cura, created by David Braam and open-sourced by Ultimaker, quickly emerged as the world’s most adopted slicing platform. As of 2025, Cura manages approximately 1.4 million print jobs each week and serves over one million global users. The scalability and customization enabled by such tools solidified slicing—not simply as a preparatory step—but as the technical core of digitally-driven fabrication for hobbyists, educators, and professionals alike. [3]

Principles of Slicing

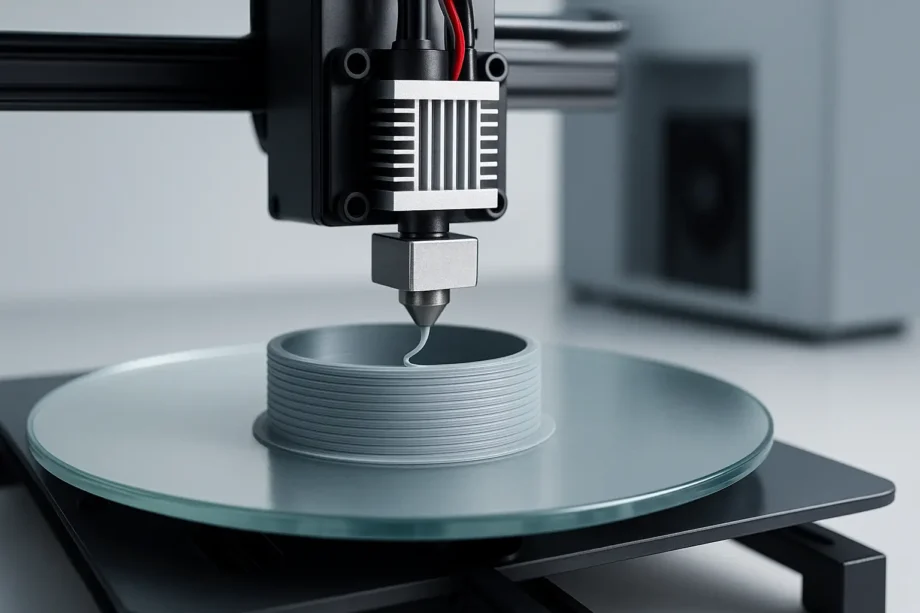

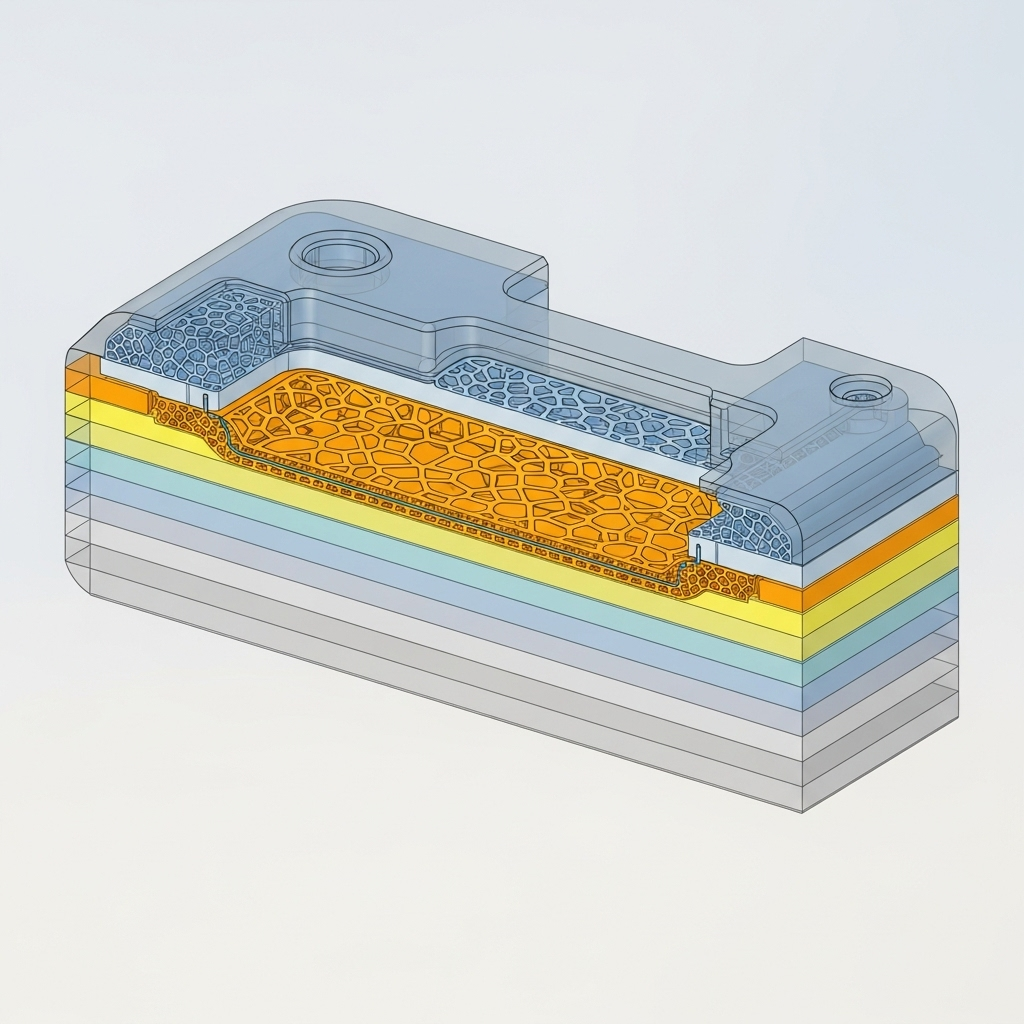

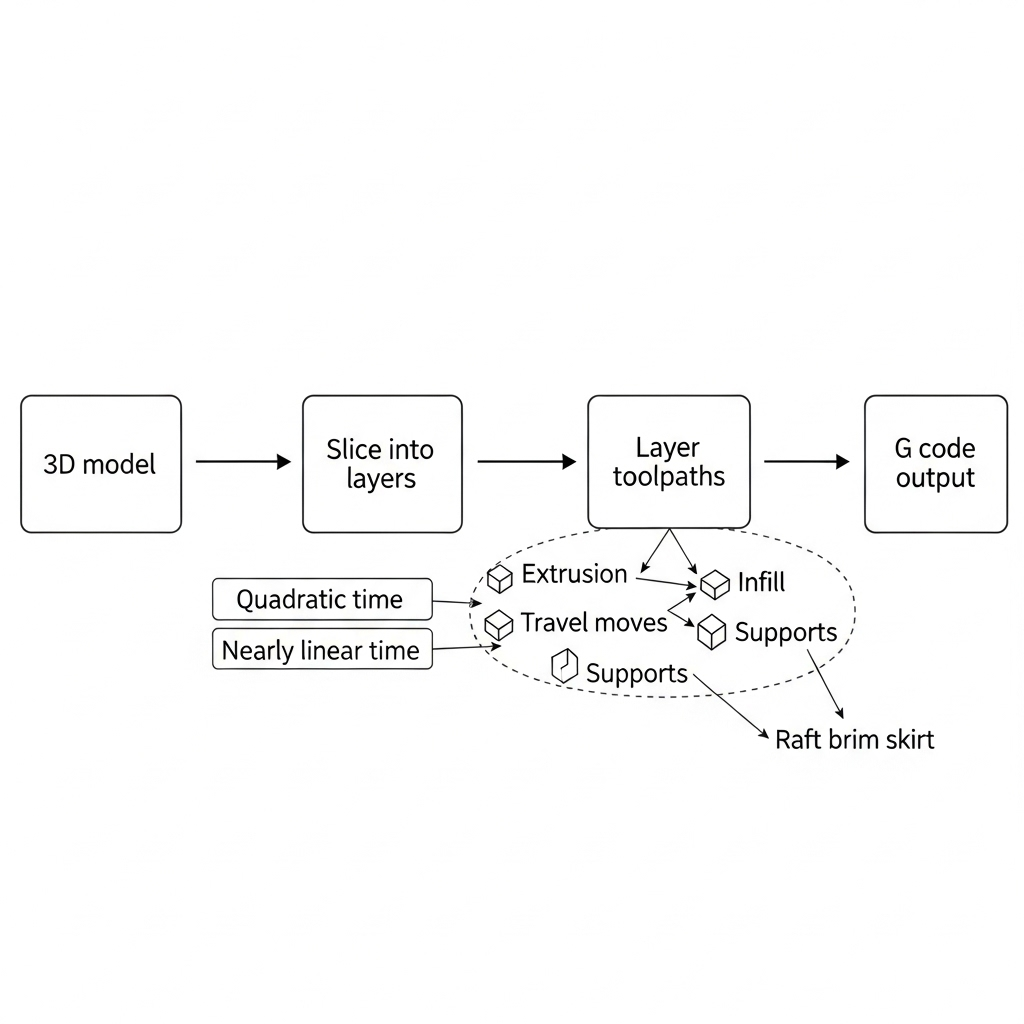

At its core, slicing software disassembles a digital model—often in STL format—into a series of flat, horizontal layers. For each of these layers, it generates toolpaths that represent the movements of the 3D printer’s nozzle or laser, tailoring instructions for extrusion, retraction, travel moves, and structural infills. Critical features handled include the addition of infill patterns, support scaffolding, rafts, brims, and skirts for print adhesion and structural stability. Upon completion of these calculations, the slicer outputs G-code, a numerical machine language understood by 3D printers. However, inefficiencies in traditional slicing algorithms, such as computational overhead and sub-optimal path generation, have been highlighted as barriers to faster, more reliable additive manufacturing—motivating extensive ongoing research into algorithmic improvements. [1][3][4]

Types of Slicer Algorithms

Basic planar slicing—implemented in many standard tools such as Slic3r and Cura—separates a model into equidistant flat layers. The approach and computational details can differ when handling mesh-based (STL) versus boundary-representation (B-rep) models, influencing accuracy and support strategy. [1]

Advanced algorithms

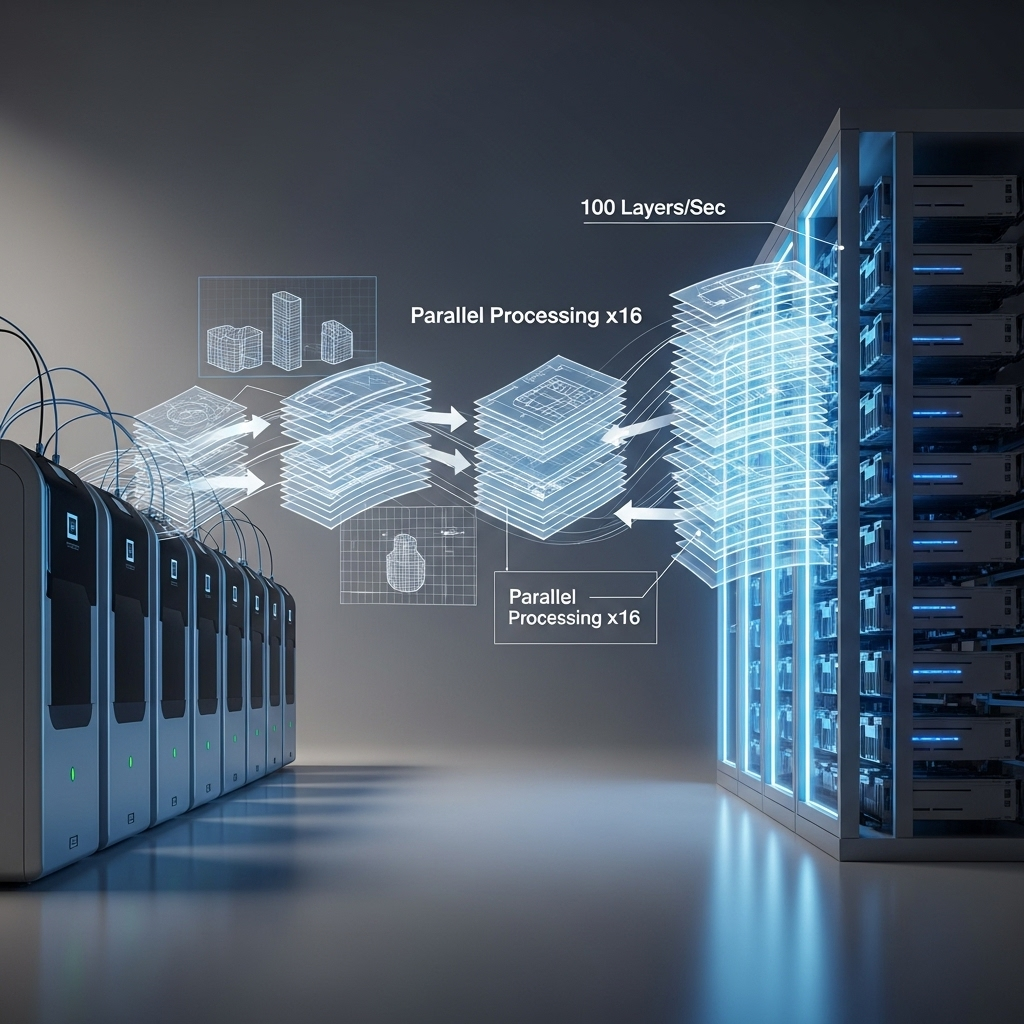

Recent research underscores diverse directions to address the technical limitations of conventional planar slicing. Topology reconstruction algorithms introduced in 2023—utilizing a mathematical approach to reconstruct the model’s surfaces per layer—exhibit nearly linear time complexity, greatly improving computational speed while preserving accuracy. Direct slicing on boundary-representation (B-rep) models further enhances results by reducing discretization errors commonly introduced by polygonal meshes and by improving the efficiency of support generation; this approach leverages the model’s inherent geometric and topological descriptors for precision. Another breakthrough exploits parallel GPU processing, where each layer’s voxel information is extracted dynamically from the model—with massive acceleration compared to sequential CPU-based approaches. These advanced algorithms offer significant benefits for applications requiring rapid preparation of complex prints, large models, or support-free fabrication, and form the basis for the next generation of slicing engines. [5][6][7]

Comparison Table — Slicing Approaches

| Method | Time Complexity | Model Type Supported | Support Generation | Speed | Surface Fidelity |

|---|---|---|---|---|---|

| Traditional Planar (STL) | Quadratic | Mesh only | Standard | Medium | Moderate |

| Topology Reconstruction | Nearly linear | Mesh/B-rep | Advanced | Fast | High |

| GPU-parallel Voxel Extraction | GPU-parallel | Mesh | Enhanced | Very fast | Moderate/High |

| Non-planar Neural | Complex | Mesh | Curved/layered | Emerging | Very high |

Performance and Efficiency

Recent algorithmic advances have produced measurable gains in slicing speed and scalability. Nearly linear time-complexity approaches, in contrast to traditional quadratic processing, have reduced the time required for preparing complex or large-scale 3D models. GPU-parallel algorithms further decrease computation duration by enabling many layers to be processed simultaneously, leveraging the data-parallel strengths of modern hardware. These improvements meet the rising demands for rapid prototyping and industrial-scale manufacturing. [5][7]

Applications

3D slicing is integral to workflows across desktop fused deposition modeling (FDM) printers, professional additive systems, and community makerspaces. Tools such as Slic3r and Cura automatically manage a suite of print parameters—including infill density, support structures beneath overhangs, and base features that secure prints to the build plate. These capabilities ensure consistent print adhesion, material efficiency, and engineered mechanical properties, underpinning both hobby-level prototyping and advanced engineering applications. [1][3]

Research Updates

The frontier of slicing research has recently expanded into neural-network based and non-planar slicing paradigms. A neural slicer algorithm introduced in 2024 utilizes machine learning to generate multi-axis toolpaths with curved layer orientations, enabling the fabrication of objects with optimized material reinforcement and—in some cases—without the need for traditional support structures. Parallel work investigates hybrid non-planar slicing techniques that combine planar and curved layer segments, delivering enhanced surface quality as quantified by Chamfer Distance measurements. The 2024 SPIE review notes that, while efficiency remains a central bottleneck in traditional slicing, progress is being made in multi-material support strategies and combinatorial path planning—pointing towards smarter, more automated slicing solutions for next-generation additive manufacturing environments. [4][8][9]

Q&A (FAQ)

1. What is 3D slicing and how does slicing software generate G-code?

3D slicing is the process of converting a digital 3D model, generally in STL format, into a set of machine-readable instructions (G-code) that dictate a printer’s actions for each print layer. Slicing software analyzes the model, calculates layer-by-layer toolpaths—including infill, supports, and peripheral structures—and then outputs this data as G-code for the printer to follow. Cura, for example, facilitates over 1.4 million print jobs weekly and serves more than a million users worldwide. [1][3]

2. When did 3D slicing begin and who created the first widely adopted slicer?

Modern 3D slicing gained traction after the release of Slic3r on 1 September 2011 by Alessandro Ranellucci. This project marked the beginning of widely adopted, open-source slicing tools for desktop 3D printing. [2]

3. Why is slicing efficiency still a research challenge?

Many slicing algorithms remain computationally inefficient, creating bottlenecks for high-resolution or complex models. The SPIE 2024 review highlights that improving both processing speed and output quality continues to be a critical research focus within the field. [4]

4. What are advanced slicing algorithm approaches in research?

Advanced slicing methods include topology reconstruction algorithms with nearly linear time complexity, direct slicing on B-rep models to minimize geometric error and improve support efficiency, and GPU-parallel algorithms for rapid, dynamic voxel extraction. These collectively address issues of speed, precision, and scalability. [5][6][7]

5. How do neural-network based and non-planar slicers improve print quality?

Neural-friendly slicing strategies enable curved layer generation, producing more robust, support-free parts and optimizing material placement. Non-planar slicers, combining planar and curved strategies, enhance surface smoothness and dimensional fidelity—demonstrated by lower Chamfer Distance errors in evaluated models. [8][9]

6. What parameters (infill, support, base structures) do slicers control?

Modern slicers give users control over infill density and pattern, support placement for overhangs, and base structures like rafts, brims, and skirts for adherence and stabilization throughout the print process. [1]

Sources

- Slicer (3D printing) — Wikipedia

- Slic3r initial release, 3Druck.com

- Cura (software) — Wikipedia

- A review of 3D printing slicing algorithms — SPIE 2024

- Nearly linear time slicing algorithm — Advances in Mechanical Engineering, 2023

- Direct slicing on B-rep models — Springer, 2019

- GPU-parallel slicing — PMC Materials, 2021

- Neural-network-based multi-axis slicer — arXiv, 2024

- Non-planar slicing algorithms — arXiv, 2024