Summary

Properly tuned 3D printer retraction settings are crucial for preventing stringing and maximizing print quality. Key parameters include retraction distance, speed, and minimum travel retraction, which control filament movement to reduce oozing between moves. For PLA, starting points are 1 mm for direct-drive extruders and 5 mm for Bowden extruders, with speed ranges of 20–60 mm/s. Adjusting these settings delivers cleaner prints on both multi-part and detailed models. [1] [2] [5]

Historical Background

Retraction became a consumer-available feature as slicer software matured during the rise of desktop fused deposition modeling (FDM) 3D printers in the early 2010s. Initial support for retraction appeared as “retreat length” in the XYZware slicer manual, and by section 11.5, the terminology and purpose were explained for new users transitioning from manual to digital slicing workflows. Enthusiasts on support forums, notably StackExchange, documented these developments and clarified how early user control over retraction distance—combined with stepper-motor driven filament—marked a turning point in combatting oozing and enhancing fine-detail print quality. [9]

Technical Principles

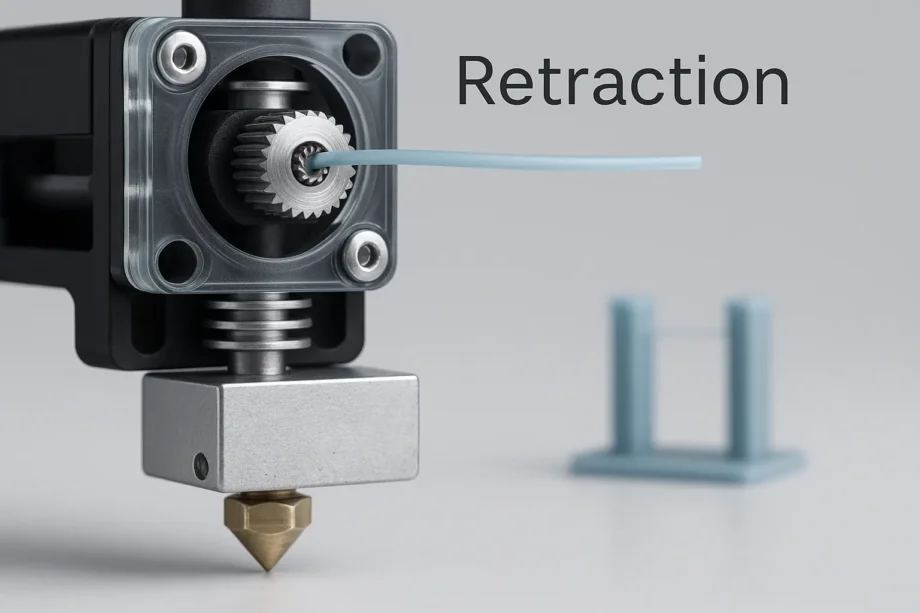

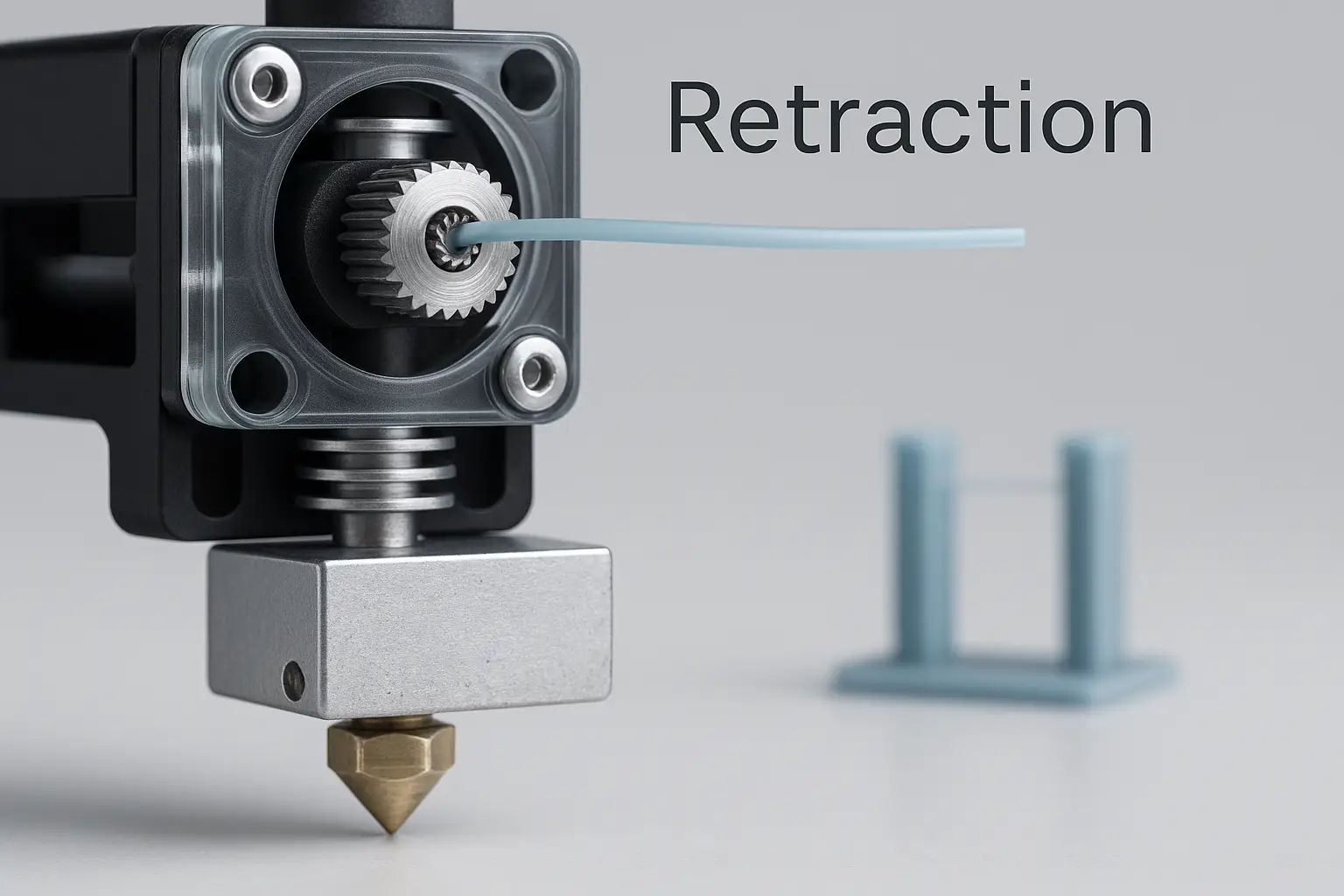

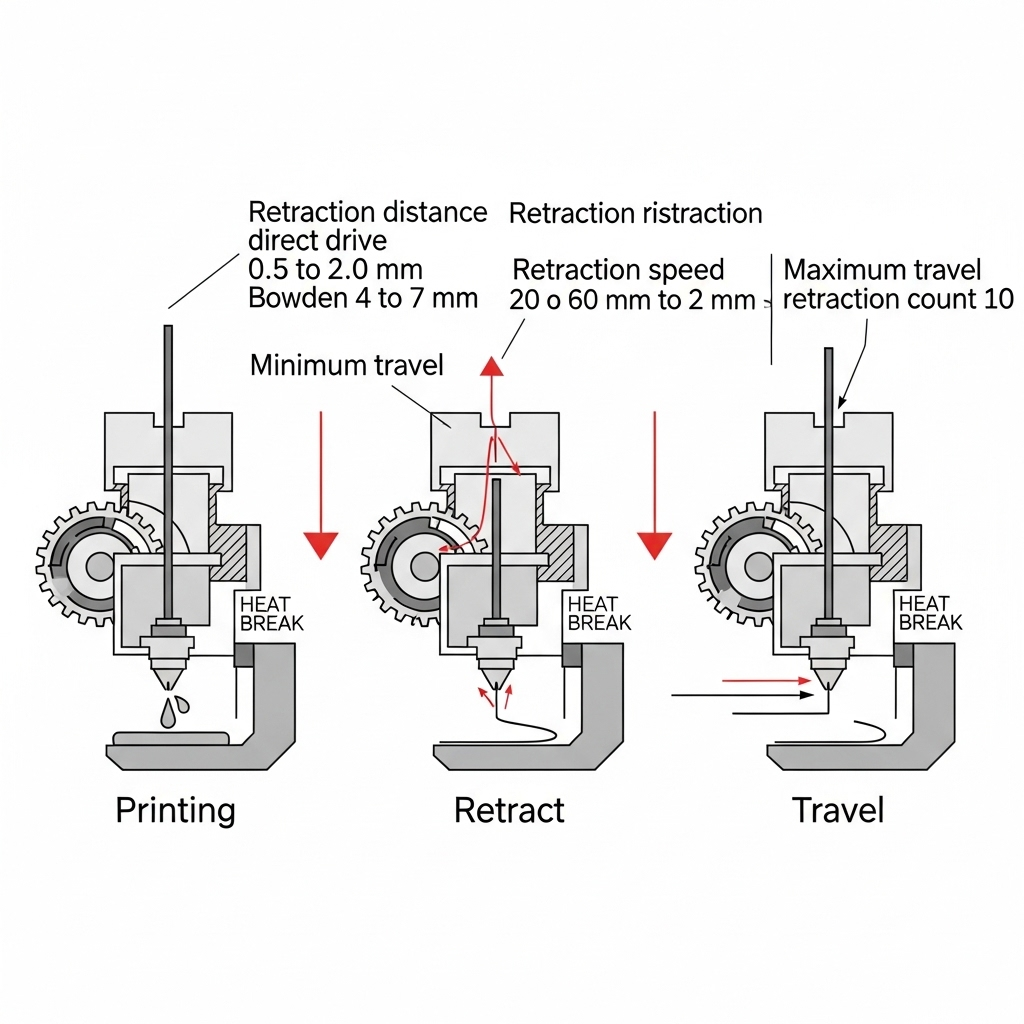

Retraction in 3D printing refers to the process where the extruder briefly reverses filament direction to relieve nozzle pressure as it travels across open spaces. By pulling filament back into the hot end, or simply unloading it slightly, the risk of molten plastic oozing and creating undesirable “strings” between separate model sections is greatly reduced. This approach is fundamental in achieving sharp, clean features, especially in prints with complex geometry or multiple islands. [9]

Core retraction settings include distance, speed, minimum travel, and maximum retraction count. Retraction distance defines how far the filament is pulled back—direct-drive setups typically require only 0.5–2.0 mm, while Bowden tubes may need 4–7 mm (rarely above 7 mm). Retraction speed is usually set between 20–60 mm/s; faster speeds reduce stringing but can cause clogs if too aggressive. Minimum travel dictates the smallest allowable movement before a retraction occurs, with recommended values of 1–2 mm to reduce unnecessary wear. Maximum retraction count, generally around 10, prevents excess wear on filament and hardware. [1] [2] [3] [4] [5] [6] [7] [8]

Common retraction setting guidelines:

- Retraction distance: Direct‑drive: 0.5–2 mm; Bowden: 4–7 mm; rarely above 7 mm

- Retraction speed: 20–60 mm/s

- Minimum travel: 1–2 mm

- Maximum retraction count: ~10

Types of Extruder Configurations

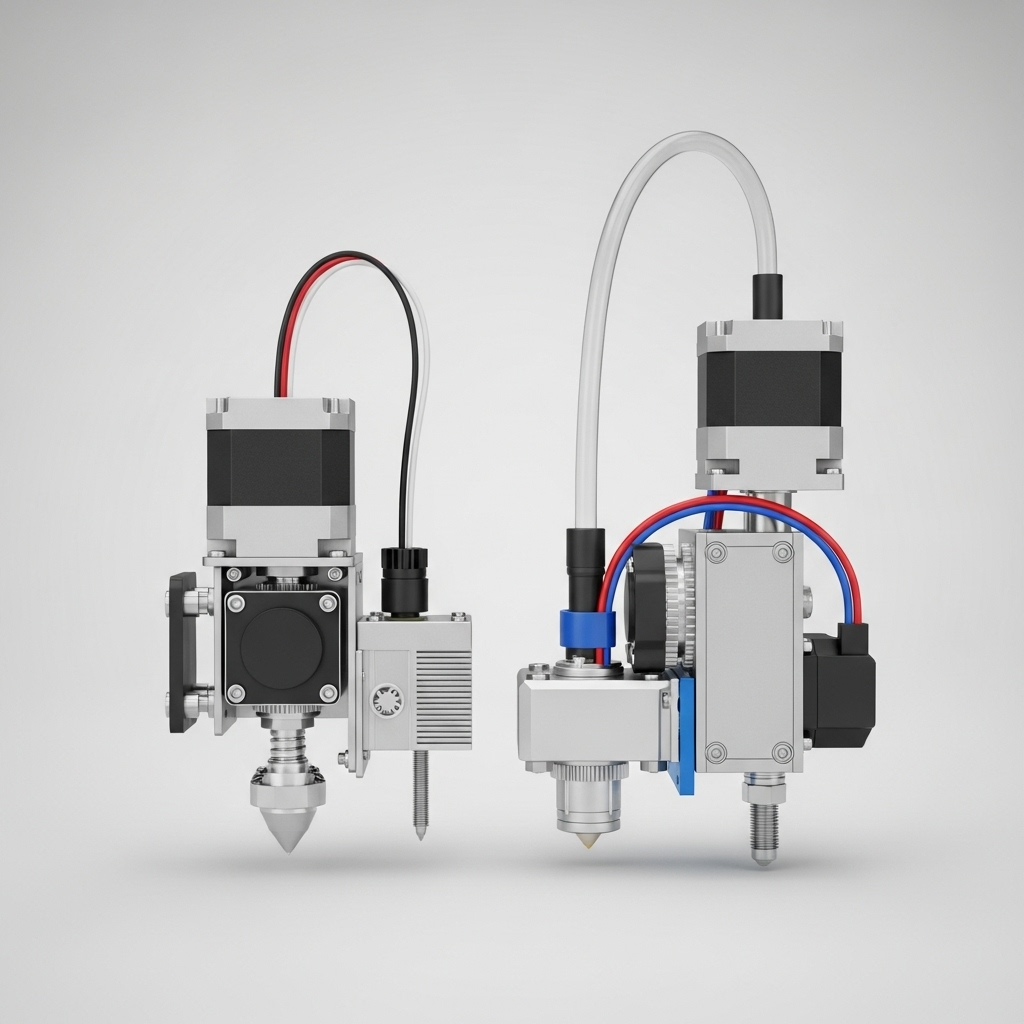

Direct‑drive extruders, which mount the extruder motor atop the hot end, generally require shorter retraction distances (0.5–2 mm) due to minimal filament flex. Bowden extruders, where filament travels through a long PTFE tube, need longer distances (4–7 mm) because of increased slack and compressibility. These distinctions are reflected in both user and slicer recommendations. [1] [2] [4] [5]

Comparative Table: Retraction Settings (Direct‑Drive vs Bowden)

| Setting | Direct‑Drive | Bowden |

|---|---|---|

| Retraction Distance | 0.5–2 mm | 4–7 mm (rarely >7 mm) |

| Recommended (PLA start) | 1 mm | 5 mm |

| Retraction Speed | 20–45 mm/s (Cura); up to 60 mm/s | 20–45 mm/s; up to 60 mm/s |

| Minimum Travel | 1–2 mm | 1–2 mm |

| Max Retraction Count | ~10 | ~10 |

Performance Optimization

Optimal 3D printer retraction tuning starts with manufacturer or slicer defaults, focusing on core ranges: 1 mm for direct-drive, 5 mm for Bowden, and speeds around 40 mm/s. Hobbyists and professionals alike recommend fine-tuning these in 0.5 mm or 5 mm/s increments, performing test prints between each adjustment. Too little distance or too slow a speed leads to persistent stringing; too much can cause jams or grinding. Iterative adjustment, combined with pattern test prints, is widely regarded as best practice. [1] [3] [5] [6]

Several related slicer settings interact with retraction and should be considered during optimization. Coasting (slightly stopping extrusion before travel), combing (confines travel moves within perimeters), and wiping (nozzle backtracks briefly at end of extrusion) all work in tandem with retraction to further minimize oozing. Print temperature, especially with materials like PLA, must also be factored in — higher temperatures increase the risk of stringing and often require more aggressive retraction and travel settings. [10]

Additional settings impacting stringing control:

- Coasting: Reduces pressure by stopping extrusion before move.

- Combing: Keeps nozzle travel within printed areas to avoid crossing open spaces.

- Wiping: Ensures the nozzle leaves a clean finish at the end of extrusion.

- Temperature adjustment: Lowering by 5–10 °C may reduce stringing in PLA.

Applications

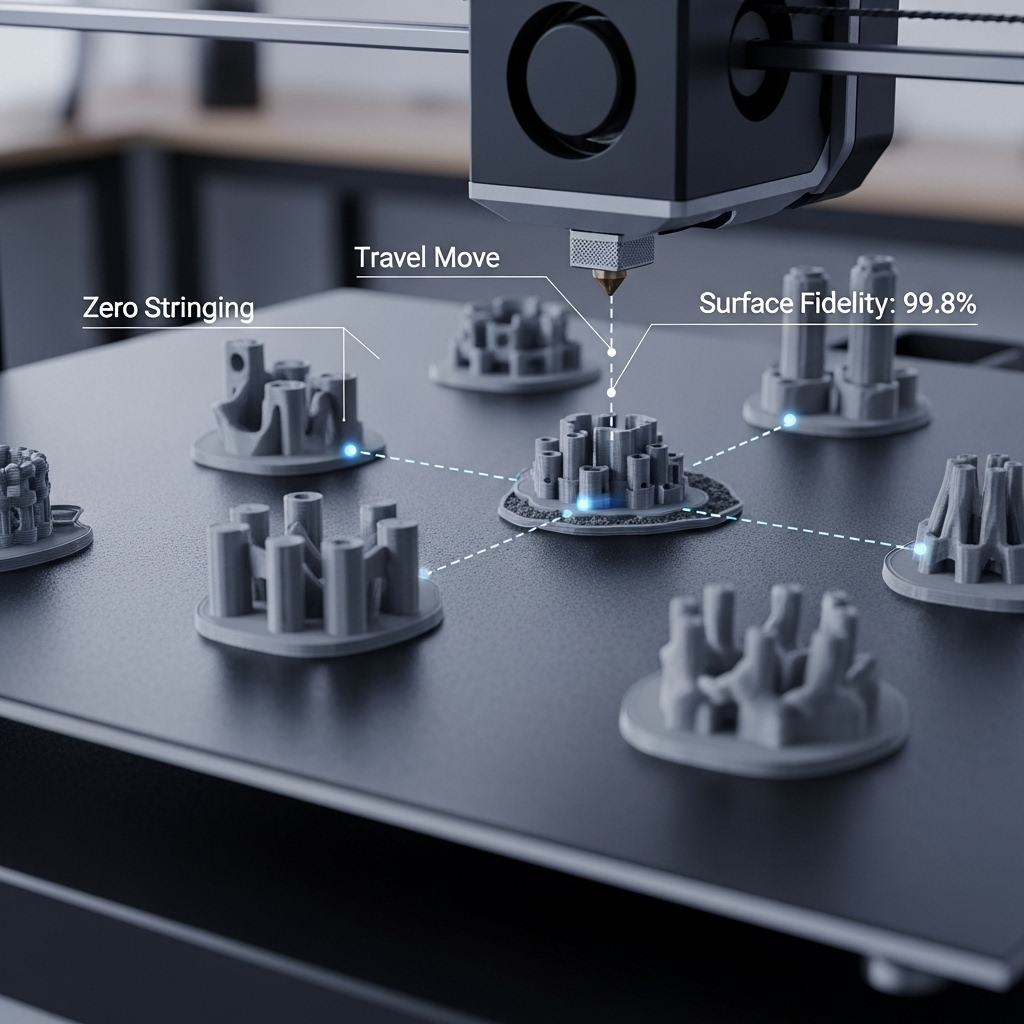

Optimized retraction settings are especially critical in 3D printing applications involving highly detailed models, miniatures, or complex multi-part builds. These scenarios, which require the nozzle to frequently cross empty areas, benefit most from well-tuned parameters to avoid time-consuming cleanup and loss of surface fidelity. [3] [5]

Research Updates

Recent advances in retraction optimization include academic and community efforts to automate calibration. Systematic testing — such as retraction towers or scripted parameter sweeps — allows users to find ideal settings for specific materials, nozzle types, and geometries. Community experiments, as documented on platforms like Reddit, use automated print towers that incrementally vary settings per test model to empirically eliminate stringing without subjective guesswork. This approach increases reproducibility and is now recommended for both home and professional users seeking to maximize print quality while minimizing print artifacts. [11]

Frequently Asked Questions (FAQ)

1. What are the optimal 3D printer retraction settings for direct‑drive vs Bowden setups?

Direct‑drive extruders typically work best with retraction distances of 0.5–2.0 mm, while Bowden configurations require 4–7 mm. Retraction speeds of 20–45 mm/s are standard, but can be increased to 60 mm/s if print quality allows. [1] [2] [3] [4]

2. How does retraction distance affect stringing fix and print quality?

Adjusting retraction distance controls how much filament is pulled back, directly relieving nozzle pressure. Proper settings minimize stringing and blob formation. Insufficient retraction leads to oozing, while excessive distance can cause jams or degraded extrusion. Recommended ranges: 1 mm (direct‑drive), 5 mm (Bowden) for PLA. [1] [2] [5]

3. What is the role of retraction speed in stringing prevention—and its risks?

Retraction speed sets how rapidly filament is reversed. Too slow, and stringing persists; too fast increases the risk of clogging and stepper missteps. Speeds between 30–60 mm/s balance performance and reliability. Experimentation is key for each printer and material. [3] [4]

4. How should the minimum travel retraction parameter be set?

Minimum travel retraction prevents retractions on very short moves, limiting unnecessary wear. A range of 1–2 mm is commonly recommended to allow retractions when needed, but avoid overuse on tiny travels. [7]

5. What is maximum retraction count and why limit it?

Maximum retraction count caps the total number of retractions within a set distance to avoid excessive filament and extruder wear. A value around 10 is standard, balancing stringing control with hardware longevity. [8]

6. Can slicer features like coasting or combing help minimize stringing beyond retraction?

Yes, slicer features like coasting (stopping extrusion before travel) and combing (moving the nozzle within perimeters) complement retraction by further reducing stringing risks and improving surface finishes. [10]

Sources

- MakerParts 3D — Tuning Retraction in 3D Printing

- 3D Print Beast — Best Retraction Settings for PLA

- Nikko Industries — What is Retraction in 3D Printing? Best Retraction Settings

- The 3D Printer Bee — Cura Retraction Settings

- 3D Insider — Avoid 3D Printing Issues Using Retraction Settings

- StackExchange — What is retract speed/length? XYZware manual cited

- Nikko Industries — Retraction Minimum Travel

- 3D Insider — Max Retraction Count

- StackExchange — Retraction Explanation (XYZware)

- 3Dx.info — Step-by-Step Guide to Retraction Stringing Elimination

- Reddit — Automated Retraction Tower Experimentation